Blog

2019-10-18

2019-10-18Cassava is one of the Philippines' main crops and contributes a lot to the Philippines' economy, with 217,000 Filipino farmers relying on cassava production.

Due to cassava is drought tolerance and requires low investment as well as the increased demand for cassava as raw materials, the cassava planting area in the Philippines has gradually increased in recent years. According to statistics, the output of cassava in the Philippines in 2015 was 2.71 million tons, an increase of 6.84% over the previous year. The main producing area of cassava in the Philippines is in Mindanao. In 2015, 1.5 million tons of cassava were produced in the area, accounting for 55.6% of the total output.

Cassava

Cassava

However, for cassava growers, it is difficult to make profits only by sell cassava. Because cassava is not resistant to storage, which is easy to rot within 48 hours, so more and more people are willing to carry out cassava processing (value added) and sales. Cassava root can be processed into various products and can replace various related raw materials. But in recent years, cassava flour production in the Philippines has attracted more and more people's attention because cassava flour is considerated as a good wheat flour substitute.

Cassava flour can replace wheat flour for food

Cassava flour can replace wheat flour for food

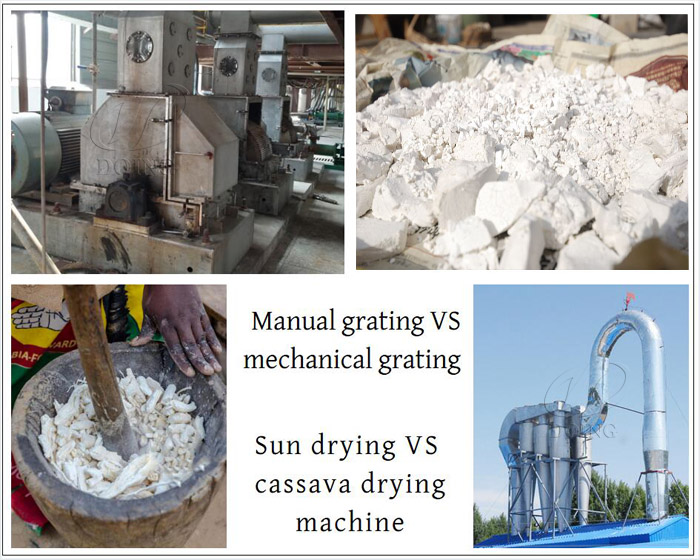

Despite this, the cassava flour production in the Philippines is not yet fully mature, and manual processing still accounts for the majority, while industrialization still has a lot of room for development. Traditional cassava flour processing requires initial processing of fresh cassava, such as washing and peeling, followed by grinding. The traditional drying of cassava flour is natural sun drying which is the most common and cost-effective method. However, the cassava flour produced by this kind method is not only low in yield, but also easily contaminated by the external environment, resulting in low quality of cassava flour.

Cassava flour grating & drying

Cassava flour grating & drying

With the development of mechanized cassava flour production in the Philippines, more plant adopts the modern cassava flour processing technology. TThis new technology can automatically and continuously process cassava into flour, using advanced high efficiency grinding machine to crush cassava, and the cassava processing after grinding is in closed environment, thus ensuring that the final product is not contaminated, and therefore enabling the cassava flour produced has high yield, high quality and meets food-grade standards. With the improvement of people's requirements for food quality, mechanized cassava flour processing is necessary and will gradually replace manual production.

Modern mechanical cassava flour processing

Modern mechanical cassava flour processing

The development prospects of cassava flour production in the Philippines

There is no doubt that cassava flour production in the Philippines is has a bright furture due to the government supports and cassava flour is more competitive than wheat flour.

1. Government supports cassava flour production

According to a study conducted by the Philippine Root Crop Research and Training Center in collaboration with the Department of Agricultural Chemistry and Food Science, many bakeries and other foods can use cassava flour to partically raplace wheat flour without affecting their quality. To reduce the Philippines' high import dependence on wheat, the Philippine government has implemented a decree aimed at encouraging and promoting the processing and consumption of cassava flour. Government support has prompted more investors to choose cassava flour production in the Philippines. Good quality cassava flour can not only replace wheat flour but also meet export demand, so the prospect of processing cassava flour in the Philippines is broad.

High quality cassava flour

High quality cassava flour

2. Cassava flour is more competitive than wheat flour

In most parts of the Philippines, root crops have evolved from major human food sources into important commercial crops and marketable products. If produced with modern technology and machinery, cassava flour can compete with wheat flour in terms of price and quality. Cassava flour can be sold at 75% of the cost of wheat flour, which can bring more profits to investors.

In summary, cassava flour production in the Philippines has a bright furture. So if you want to start cassava flour processing business, please contact Doing Machinery, we can customize the most suitable solution for you.

Want to know more about our products or services? Fill out the contact form below, and we’ll to get back to you and you will get the price list. Please also feel free to contact us by email or phone.( * Denotes a required field).