Project

2025-09-26

2025-09-26Congratulations! 3tph combined garri and cassava flour processing project was successfully installed in Nigeria!

Project Overview:

Project name: Garri and cassava flour processing project

Capacity: 3tph output capacity

Products: garri and cassava flour

Project site: Nigeria

1. What is the Nigerian client's vision?

Our client, a seasoned agribusiness entrepreneur in Nigeria, would like establish a modern, efficient cassava processing plant that could transform large volumes of raw cassava into both high-quality garri and cassava flour. He required a significant output of 3 tons of finished product per hour.

raw cassava tubers

raw cassava tubers

2. What is Henan Jinrui's Tailored Solution?

After understanding the Nigerian client's needs, we recommended a complete set of integrated cassava processing machinery to him.This solution perfectly matched the client's need for a versatile plant capable of switching between garri and flour production with minimal downtime.

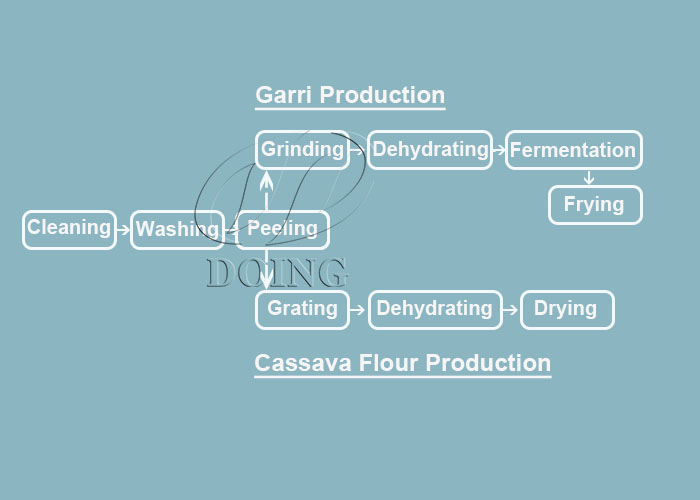

Process Flow:

For garri: cleaning--washing--peeling--grating--fermentation--dewatering--frying--sieving

For cassava flour: cleaning--washing--peeling--grating--dewatering--drying--sieving

garri and cassava flour process flow

garri and cassava flour process flow

Equipment Included:

Cleaning: A cassava dry sieve and paddle washer to remove all dirt and sand.

Peeling: Efficient cassava peeling machine to remove skins.

Grating: High crushing rate cassava grate to crush cassava into mash

Dewatering: A robust hydraulic press to remove water from the grated mash

Drying: An automatic garri frying machine for perfect toasting and a flash dryer for drying cassava flour.

Sifting: A vibration sieve to produce smooth, uniform garri or cassava flour.

Automated Control: A central control system to make operation simple and efficient.

garri processing machine

garri processing machine

3. What is The Journey From Order to Operation?

Step 1: The Alibaba Connection & Detailed Communication

The Nigerian client found us on Alibaba and sent an inquiry on cassava processing machinery. We moved quickly to a video call to discuss their specific needs, factory layout, and power supply. We provided detailed CAD layout drawings to help them prepare the factory floor even before the shipment arrived.

Step 2: Order & Secure Payment

The Nigerian client felt confident proceeding. The order was finalized, and we used Alibaba's Trade Assurance service. This protected the client's payment, ensuring it was only released to us after they confirmed satisfactory delivery.

cassava flour processing machine

cassava flour processing machine

Step 3: Proactive Transportation & Logistics

Henan Jinrui's logistics team handled all export formalities to avoid delays and damage. We used experienced freight forwarders familiar with the destination port (e.g., Lagos). All machines were professionally crated and secured in a 40-foot HQ container to prevent rust and damage during the long sea voyage. We provided all necessary shipping documents well in advance.

Step 4: On-the-Ground Installation & Support

We included the services of one of our senior engineers as part of the package. Our engineer in Nigerian branch office for on-site installation, commissioning, and training. He worked alongside the client's team for two weeks, ensuring every machine was calibrated correctly and the local operators were fully trained on operation, safety, and basic maintenance.

We here sincerely wish our Nigerian client's garri and cassava flour processing project operate smoothly and bring more benefits to him! Also, Henan Jinrui's Nigerian branch office will further give supports to his project!

Want to know more about our products or services? Fill out the contact form below, and we’ll to get back to you and you will get the price list. Please also feel free to contact us by email or phone.( * Denotes a required field).