Blog

2023-01-11

2023-01-11The low quality of starch is mainly due to the processing method. Therefore, choose the appropriate starch processing method is the key to solve the problem of low quality cassava starch.

In traditional way, people use manual method to produce starch. The material roots are crushed firstly, and then use cloth to sieve fibers, finally get starch after long time precipitation and dry under sunlight. Starch produced from manual method is in low quality, because there are some non-starch substances are not separated.

Starch quality comparison

Starch quality comparison

How to improve starch quality that is produced from manual method?

Firstly put water into starch to make slurry, then use de-sander machine to separate sand impurities. And then pump starch slurry to hydrocyclone station to remove non-starch substances like protein, fine fibers and cell liquids. After that, you will get purified starch, and then use dehydration machine and drying machine to get final high quality starch.

Although there is good solution for improving quality of manual produced starch, it has low efficiency and cannot achieve large scale production. Therefore, automatic starch processing method begins to repalce manual method, which introduces advanced technology and machines to make high quality starch directly from raw materials.

So what is automatic starch processing method like?

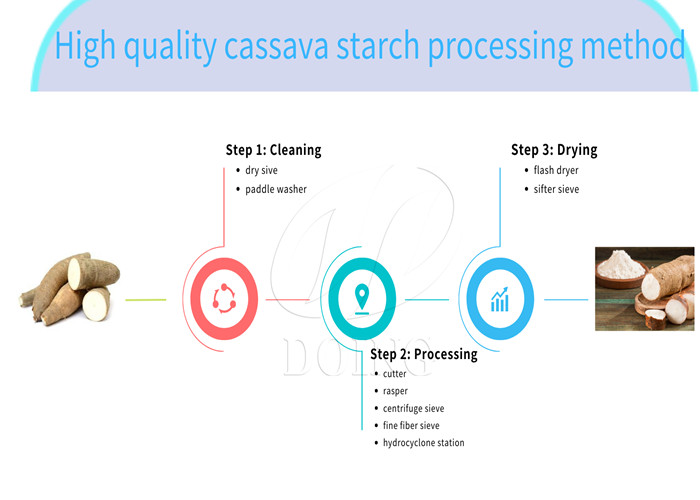

Automatic starch processing method means to produce starch with advanced machine fully, which can not only improve production effeciency but also guarantee the high quality of starch. The production process mainly includes: cleaning, processing and drying.

Cleaning section

Firstly raw material roots are put into feeding hopper, and then transported by conveyor to dry sieve machine. The dry sieve machine will remove attached impurities on materilals. After that, cassava will drop down into paddle washing machine for complete cleaning. Tips: the machine of cleaning section can adjust according to your capacity and material characters.

Processing section

Cleaned material is cut into small pieces firstly, and then crushed by rasper machine. Followingly, cassava mash will be pumped into centrifuge sieve to separate fibers, then go through de-sander machine to remove sand, finally pumped into hydrocyclone station to remove other non-starch contents. After that, we can get purified starch milk.

Drying section

Purified starch milk will be sent to dehydrator machine to get wet starch with moisture content around 40%. And then wet starch will be conveyed into flash dryer to dry completely, getting final starch with moisture content around 12%. Finally sieving machine can be installed to ensure fineness of starch powder.

How to produce high quality starch?

How to produce high quality starch?

In a word, manual processing method is suitable for small scale production. Automatic processing method is suitable for medium and large scale starch production.

To solve the problem of low quality starch completely, it cannot be realized without the help of advanced starch processing machine. Whatever single starch processing machine or complete starch production upgrade, Henan Jinrui can give you a hand. If you want to know more details, feel free to contact us any time.

Want to know more about our products or services? Fill out the contact form below, and we’ll to get back to you and you will get the price list. Please also feel free to contact us by email or phone.( * Denotes a required field).