Blog

2021-03-26

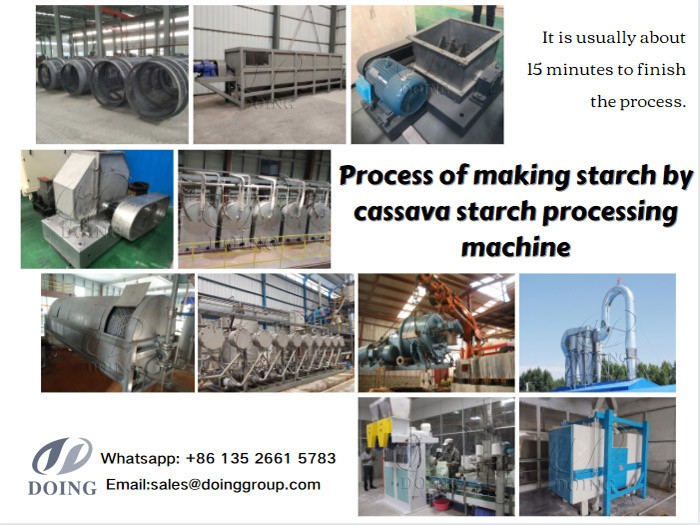

2021-03-26The process for cassava processing into starch consists of 3 parts: cleaning section, processing section and drying section.

Cassava starch processing

Cassava starch processing

Cleaning section:

The cleaning section is also called raw material pre-treatment process. It is the first step for cassava processing. Dry sieve machine is designed to remove outer impurities attached on cassava roots. And paddle washing machine is to clean cassava tubers completely by water.

Processing section:

The processing section is also called raw material crushing and starch extraction. Firstly cutting machine and rasper will crush cleaned cassava. And rasper machine can crush material to the greatest extent and get starch released as much as possible. The centrifuge sieve machine is used to separate solid fibers, and fine fiber sieve can eliminate tiny fibers. After that, cassava liquid will be pumped to hydrocyclone station to remove liquid impurities like protein, fats, cell liquids etc. Finally refined starch milk will be got and pumped into transfer tank for next process.

Cassava starch processing machine

Cassava starch processing machine

Drying section:

The third and last is drying section, which is divided into dehydration drying and sieving. Considering characteristics of cassava starch particle size, peeler centrifuge is the best choice for dehydration. There is scraper design and back washing system inside peeler centrifuge which can ensure sieve permeability and prevent starch clogging, so as to maintain the low starch moisture content after dewatering. And then wet starch will be transported to flash dryer for last drying process. After dehydration, starch moisture content is around 38-40%, which will be reduced to 10-14% after drying. Final moisture content also can be adjusted according to client’s request.

The above is the process for cassava processing into starch. If you want to know more details, feel free to contact us any time.

Want to know more about our products or services? Fill out the contact form below, and we’ll to get back to you and you will get the price list. Please also feel free to contact us by email or phone.( * Denotes a required field).