Blog

2025-08-20

2025-08-20While Uganda ranks among Africa’s top cassava producers, it trapped in a cycle of low-value raw exports or subsistence use. Yet driven by global food trends and African policy reforms, cassava flour has become a high-growth commodity. Building cassava flour processing plant in Uganda promises to increase cassava added value and integrate into international supply chains.

cassava flour business uganda

cassava flour business uganda

The Rising Global Market: Policy Shifts and Health Trends Driving Demand

1.African Import-Substitution Policies

African nations are actively reducing costly wheat imports by mandating cassava-wheat flour blends:

Nigeria leads with a 50% cassava flour blend policy, saving $2 billion/year on wheat imports while boosting domestic cassava farming. Uganda’s neighbor Tanzania enforces a 10% blend, and Ghana targets 20%. These policies create captive domestic markets for cassava flour, ensuring immediate offtake for Ugandan processors.

2. Global Health and Functional Food Boom

Beyond Africa, cassava flour’s nutritional profile aligns with booming dietary trends:

Gluten-free demand: With 15–20% of Western consumers avoiding gluten, cassava flour serves as a neutral-tasting, grain-free alternative in baked goods, snacks, and pasta. The global market hit $52.4 billion in 2024 and grows at 6.2% annually.

3. Industrial Applications

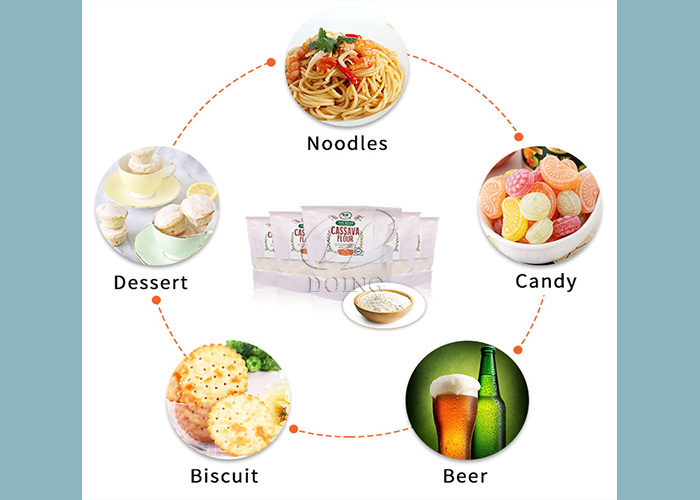

Beyond the health food aisle, cassava flour is a vital raw material for numerous industries. It is used in the production of biofuels, animal feed, pharmaceuticals, textiles, and paper, creating a diverse and resilient demand base.

cassava flour usage

cassava flour usage

The Local Opportunity: A Vast and Unmet Potential

1.Outdated processing technology: Uganda is the third-largest producer of cassava in Africa, with an annual output of millions of tonnes. However, in the severe lack of modern processing infrastructure. Most cassava is still processed using traditional, inefficient methods, failing to meet the quality and safety standards required by premium international markets.

2. Domestic unmet markets: From the staple posho (maize flour) substitute to the booming restaurant and hotel industry seeking gluten-free options, the domestic demand for quality cassava flour is immense and largely unmet.

The Government's Hand of Support: Policies and Incentives

The Ugandan government has implemented many policies to give supports, for example:

1.Emphasis on Priority Crops: Cassava has been designated a key strategic crop under government programs like the Parish Development Model (PDM), which aims to increase household incomes by boosting production and value addition at the grassroots level.

2.Investment Incentives: The Uganda Investment Authority (UIA) offers numerous incentives for agro-processing ventures, including tax exemptions on imported machinery, duty-free importation of plant equipment, and support in securing land and necessary permits.

The Final Piece: Modern, Efficient Processing Technology

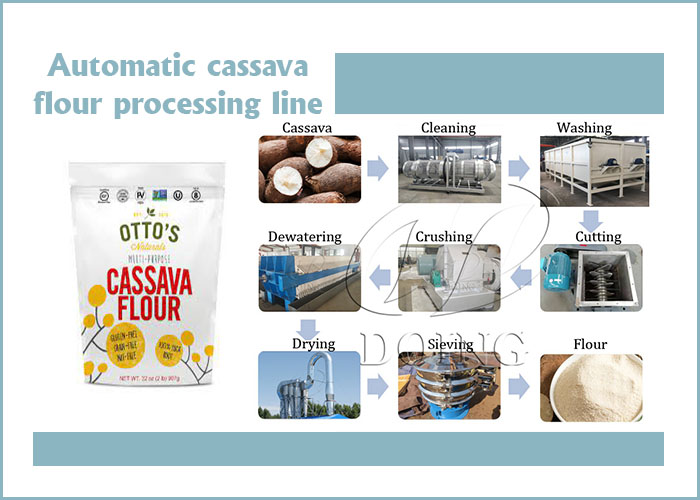

Modern cassava flour processing machines have evolved to be highly efficient, scalable, and adaptable to the Ugandan context.

cassava flour processing machines

cassava flour processing machines

Cassava Cleaning and Washing Machines: To remove all dirt and sand.

Cassava Peeling Machines: To peel cassava skins.

Cassava Raspers (Graters): To pulverize the roots into a mash.

Cassava De-watering Presses: To extract excess water and reduce drying time and energy costs.

Cassava Drying Machine: To dry cassava flour with high efficiency.

Cassava Milling and Sieving Machines: To grind the dried granules into a fine, uniform flour and sieve it to the desired particle size.

If you want to build a cassava flour processing plant in Uganda, feel free to chat with us! Henan Jinrui has provided cassava processing machines for many years. No matter you want to choose small single machines for initiative production, or invest in a complete line to realize scaled production, we can tail plans to meet your demand!

Want to know more about our products or services? Fill out the contact form below, and we’ll to get back to you and you will get the price list. Please also feel free to contact us by email or phone.( * Denotes a required field).