Blog

2023-04-26

2023-04-26For the factors that influence the cassava starch yield of cassava starch production, three aspects should be considered: the starch content of raw cassava, the processing technology for cassava starch production, and the proficiency in operating skills.

Factor1: The starch content of raw cassava

The starch content of raw cassava will affect the final cassava starch yield of cassava starch production. Different varieties of cassava tubers have different starch content, which will be between 20-30%. And cassava harvested from the dry season has more starch content compared to that harvested from the raining season. If the starch contents of your raw cassava is no less than 23%, machinery provided by Henan Jinrui can guarantee you that 4 tons cassava can produce 1 ton starch.

Factor2: The Processing technology for cassava starch production

Two factors that influence cassava starch yield should be considered in the whole process of cassava starch production: one is to release starch as much as possible, and the other is to reduce starch lost during the separation of impurities. Crushing rate, soaking time, separation and drying effect in cassava starch processing will affect the starch yield.

The crushing rate of crushing machines

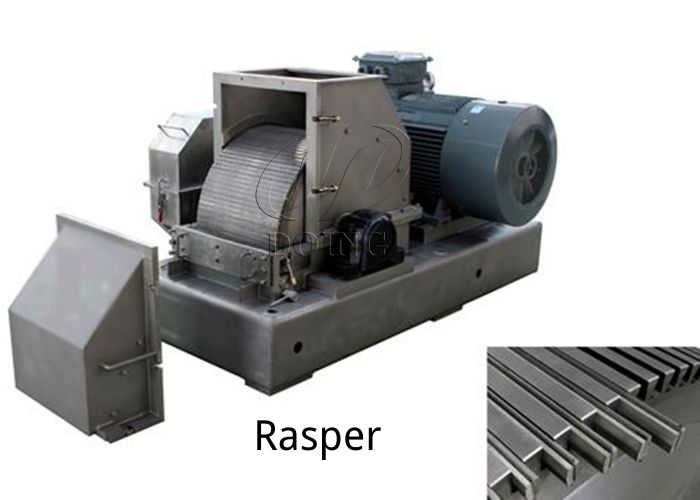

Starch exists in cassava tubers as free starch and bound starch. Bound starch mainly exists in the cell wall, which means only cell wall is broken, the starch can be released. In other words, the more thoroughly the cassava is crushed, the more cassava starch is released. Henan Jinrui company adopts a rasper machine in the crushing section. At a 2000r/min high rotation speed, its crushing rate can achieve 96-98%. Compared with hammer crushers whose crushing rate is only 80%, or normal graters whose rate is even much lower, it is the highest crushing co-efficiency in the market.

Rasper for cassava starch production

Rasper for cassava starch production

The soaking time of crushed cassava

In order to ensure the cassava starch yield and quality, cassava needs to be soaked after chopping to remove impurities and proteins in the starch. The conventional soaking time is about 12-24 hours. If it is too short, the starch will not be completely dissolved, thereby the cassava starch yield will decrease, while if too long, the cassava starch will be easily deteriorated, degraded or polluted, and the purity of the starch will reduce.

The separation effect of cassava starch separating machines

In the fiber separation and protein separation stage, Henan Jinrui company has a special design to reduce the starch loss and can ensure a cassava starch extraction rate of no less than 94%. Compared to the vertical type, Henan Jinrui company adopt a horizontal centrifuge sieve machine, having a higher rotation speed so that fiber separation is more thorough. Besides, after the fiber is separated from 1st stage, the 2nd stage will add water to wash the fibers again to reduce starch lost along with the fibers. Normally in our design, 4-5 stages are applied. As for protein separation, Hydrocyclone station is used to remove protein and cell liquids, ensuring starch quality. Generally speaking, the more stages of hydrocyclone are used, the higher quality of the final product will be. Considering expected economic profits and starch extraction quality, the 18-stage design with starch concentration, refining, and recycling all in one, is the best solution.

Centrifuge sieve and hycyclone station

Centrifuge sieve and hycyclone station

The drying machine in cassava starch production

Reducing the starch loss in the drying part of cassava starch production line can ensure cassava starch yield. Negative pressure is adopted in the flash dryer. When the flash dryer is running, the inside pressure of drying tubes is lower than that of the outside, therefore starch will not leak into the air. And starch discharge cyclone has a special design on angles, no starch will be lost through exhaust pipes.

Flash dryer for cassava starch drying

Flash dryer for cassava starch drying

Factor3: The proficiency in operating skills

The proficiency of operation skills will also affect the cassava starch yield, and improper operation in cassava starch production will lead to the loss of starch. Generally speaking, the following operators need to be arranged in the cassava starch production line: an equipment operator responsible for the operation, maintenance, and upkeep of starch processing equipment; a starch extractor mastering the techniques and methods in the starch processing process, responsible for extracting, filtering, dehydration, drying, and other operations on starch;a raw material processing worker responsible for the cleaning, peeling, shredding and other preliminary processing work of raw materials, and an inspector responsible for inspecting the quality and qualification rate of starch products.

The above is a brief introduction to key factors that influence cassava starch yield of cassava starch production. If you have such a plan to set up a cassava starch factory, feel free to contact us any time.

Want to know more about our products or services? Fill out the contact form below, and we’ll to get back to you and you will get the price list. Please also feel free to contact us by email or phone.( * Denotes a required field).