Blog

2020-11-25

2020-11-25In flash drying process, starch drying equipment is a key equipment. The entire flash drying process adopts an automatic control system, which can pre-set the drying program through intelligent control, measure the feed moisture and air temperature difference, and automatically adjust the feed volume and air intake volume. Finally it can dry the starch to a specified level to ensure the starch stability of moisture. For better starch processing, when there is the problem of starch with high water content in flash drying process, taking some steps is necessary. So how to solve the problem of starch with high water content in flash drying process?

How to solve the problem of starch with high water content in flash drying process

How to solve the problem of starch with high water content in flash drying process

Problem 1. Poor starch drying effect, high moisture content of dried starch

Sometimes the dried starch has a high moisture content. It is because the dried starch stays in the drying pipeline for a short time, the feed amount is too large, or the previous starch dewatering has a high moisture content. All these will result in the poor starch drying efficiency in flash drying process.

How to control the feed amount and material residence time to lower the water content of starch in flash drying process?

In this case, the length or angle of the drying pipe in flash drying process can be adjusted to help control the feed amount and material residence time. Then the final dried starch will have a lower moisture content which is soft and delicate.

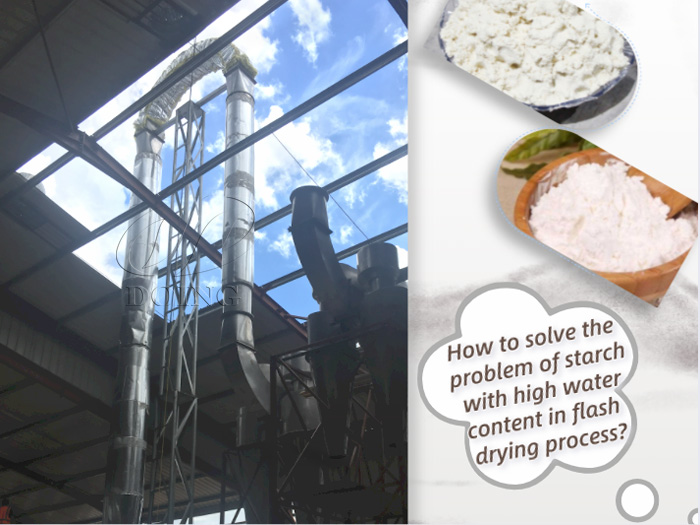

Flash drying machine is working

Flash drying machine is working

Problem 2. Loose interface and leaking rotary joint lead to low efficiency, starch will has a high water content

When dried starch enter into the flash drying process, if the interface of the flash drying equipment is not tight and the rotary joint leaks, the power of the fan will be weakened and the rotation speed will slow down. Finally the insufficient power will lead to starch with high water content in flash drying process.

How to solve the problem of loose interface and leaking rotary joint in flash drying process?

Check whether there is any looseness at the interface of links, and tighten or weld in time. If it is leaking, the gasket may be damaged, so replace it in time. So when we use the starch processing machine, we should operate safely, inspect timely, and timely replace worn-out parts to avoid further losses caused by increased wear. By this way, we can improve the starch drying efficiency in flash drying process.

As the last but important process, if the final starch with high water content in flash drying process, the whole starch processing is bound to suffer a loss. Only with the good maintenance of equipment, can the starch processing has a smooth production. If you have more questions about the flash drying machine, please contact us.

Want to know more about our products or services? Fill out the contact form below, and we’ll to get back to you and you will get the price list. Please also feel free to contact us by email or phone.( * Denotes a required field).