Blog

2021-01-21

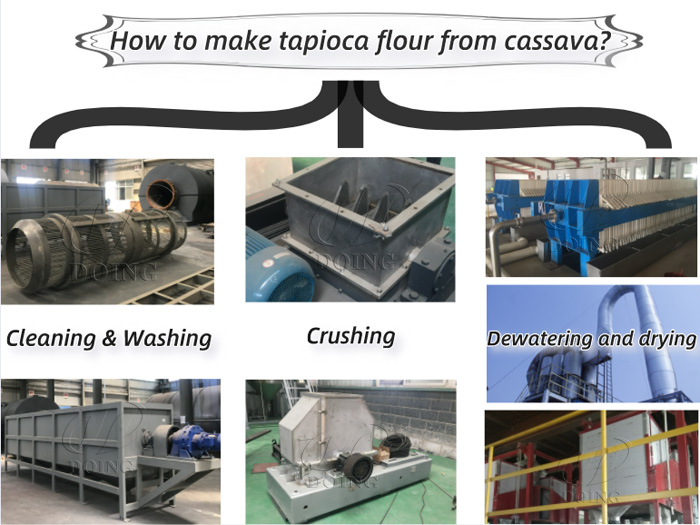

2021-01-21The high quality cassava flour production is always produced by machine. The raw material is cassava and the final product is cassava flour. Also the high quality cassava flour production means high automation. If you want to produce high quality cassava flour, cassava flour making machine is necessary.

How to produce high quality cassava flour? There are 3 factor. They are cassava raw material quality, processing technology and cassava flour machinery selection.

How to produce HQCF

How to produce HQCF

The first is raw material cassava tubers. To produce high quality cassava flour, fresh cassava tubers that harvested within 3 days are used for cassava flour processing. Because the raw material is relatively fresh and will not be oxidized which can ensure whiteness of final cassava flour. Besides, cassava tubers should be in good quality, clean and free of decomposing.

The second factor is processing technology. You had better choose wet processing technology which use fresh cassava tubers as input and can achieve continuous production from raw material to final cassava flour. Because the short contact time between material and air can ensure the whiteness of finished product.

High quality cassava flour production

High quality cassava flour production

To produce high quality cassava flour, apart from good quality raw cassava tubers and modern processing technology, cassava flour machinery selection is also important. It mainly reflects in crushing process and drying process. In crushing processing, rasper is needed which has higher linear speed and compact structure. It can crush cassava tubers to the maximum extent and ensure the fineness of final flour. In drying section, flash dryer should be used to dry wet flour in very short time. Because the negative pressure is adopted which can keep loss of final flour and cleaning working environment inside workshop. What’s more, all parts that may contact with cassava material should be made of food grade stainless steel 304 which can easily clean and is safe for food.

If you have plan to set up a factory to have a high quality cassava flour production, feel free to contact us for complete proposal.

Want to know more about our products or services? Fill out the contact form below, and we’ll to get back to you and you will get the price list. Please also feel free to contact us by email or phone.( * Denotes a required field).