Blog

2025-09-10

2025-09-10From cassava to revenue, how do you realize it this magical change? The key lies on smart cassava processing machinery! Traditional cassava processing methods are often plagued by inefficiency, high waste, inconsistent quality, and low profit margins. In contrast, smart cassava processing machinery can strategically engineer the cassava operation to maximize yield, ensure quality, and boost revenue.

Now, let's take cassava flour production as an example, and see how smart cassava processing machinery empower HQCF production!

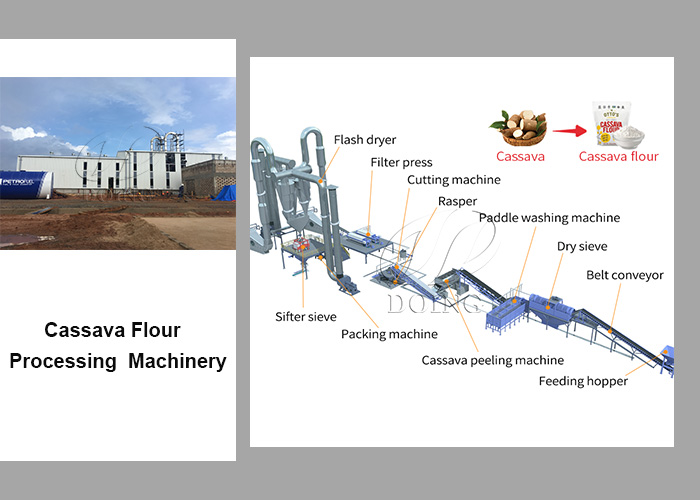

cassava flour production line work flow

cassava flour production line work flow

How does smart cassava processing machinery reduce raw material waste and maximize yield?

In the cassava flour production line, smart cassava processing machinery minimizes tuber waste and maximizes starch extraction through precision engineering in three critical stages: peeling, grating, and drying.

Cassava peeling part: Cassava peeling machinery designed with sand rollers adopts abrasive principle to remove cassava skins. It is designed with an optimal abrasive grit size and roller speed to remove only the thin, outer peel and cortex where toxins like cyanogenic glycosides are concentrated. Compared to manual peeling, which can remove significant amounts of starchy flesh along with the peel, this abrasive technology reduces starch loss to less than 2-3%, which means higher utilization rate of raw materials and higher yield of cassava flour.

Cassava grating part: Cassava grating machinery, here referring to cassava rasper, is able to grind cassava into slurry. The finer the slurry, the higher the yield. The fineness of cassava flour slurry is a direct function of rasping speed and tooth design. Smart cassava raspers operate at controlled high speeds (often over 1,500 RPM) to smash the cassava root cells completely. It can achieve a pulp consistency of under 200 microns, ensuring over 98% starch liberation from the root. This maximizes the potential yield right at the beginning of the cassava flour process.

Cassava drying part: Cassava flour drying machinery, also named flash dryer, dry wet cassava flour in 1-2 seconds. This dryer adopts negative pressure drying principle to enhance hot transformation rate, largely reducing drying time as well as lowing energy consumption. Fully sealed design extremely prevent flour leakage, indirectly increase yield. After this process, the moisture of cassava flour can be down to 12-14%, meeting standard requirements.

How does smart cassava processing machinery perfectly control the cassava flour consistency?

Consistency is the symbol of High-quality cassava flour. Equipped with PLC system, the whole process of cassava flour processing line is visible and adjustable. You can pre-set parameters in advance to control the operation of cassava processing machinery, ensuring the consistency of final flour.

The PLC coordinates all units of cassava flour production line:

It controls the feed rate of cassava into the cassava washer and peeler to prevent overload.

It regulates the water flow in the washing system for optimal cleaning as well as reducing water consumption.

It monitors the motor load on the rasper to ensure consistent grinding efficiency.

It dynamically adjusts dryer temperature, airflow, and conveyor speed based on real-time moisture feedback, ensuring the cassava flour is dried to the exact pre-set moisture level (e.g., 12%) .

Smart cassava processing machinery contributes a lot to minimizing raw tubers waste and maximizing cassava flour yield, driving the growth of revenue. Wanna learn more about the setup of different capacity cassava flour production line? Tell us your ideal capacity! No matter a small one begins with 1-2 tph or a large one with 30-40tph, we, Henan Jinrui, can customize a solution catering to your needs!

Want to know more about our products or services? Fill out the contact form below, and we’ll to get back to you and you will get the price list. Please also feel free to contact us by email or phone.( * Denotes a required field).