Blog

2020-07-08

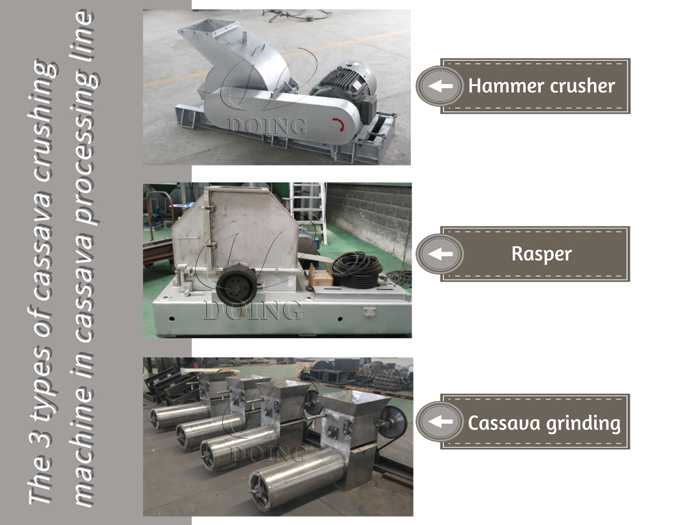

2020-07-08In cassava processing line, it is necessary to use cassava crushing machine to fully crush cassava raw materials so that the starch particles can be set free, then we can get final starch. There are 3 types of cassava crushing machine in Doing Holdings - Henan Jinrui, mainly including hammer crusher, rasper and cassava grinding machine. Different cassava crushing machine is surely different in many ways. Next it is the introduction of the 3 types of cassava crushing machine in cassava processing line.

3 types of cassava crushing machine

3 types of cassava crushing machine

Hammer crusher: It can be used for crushing tuberous roots such as cassava, potatoes, sweet potatoes, etc. It is mostly used for the crushing of wet cassava flour in the cassava flour production line.

Hammer crusher is a device that uses high-speed rotating blades to crush raw materials which is mainly composed of a casing, a reducer, a motor, a rotating knife holder, etc. The features of hammer crusher: reasonable design, low energy consumption, large output, full crushing, and convenient maintenance.

Hammer crusher

Hammer crusher

Rasper: Rasper can be used for cassava, potato and sweet potato processing line to grind and crush raw materials. Doing Holdings - Henan Jinrui's rasper is designed and manufactured according to the characteristics of domestic and foreign experience.

It has a compact structure which is high speed and has a high coefficient of raw material grinding. It can easily break up the raw material cells and free the starch. Doing Holdings - Henan Jinrui's rasper can achieve two-way crushing which has a large processing capacity and high crushing rate. It is easy to replace the bottom net, easy to set up and easy to operate. The rasper is also equipped with Swedish SKF bearings and German belts, which is durable and has a long life.

Rasper for cassava crushing

Rasper for cassava crushing

Cassava grinding machine: It is also known as starch separator which is an integrated machine for crushing, separating and filtering raw materials. It is especially suitable for farmers' scattered processing and small-scale processing line. It is suitable for customers with small planting area or limited cost budget.

The cassava grinding equipment is mainly composed of body, roller, main shaft, base, filter screen and so on. Doing Holdings - Henan Jinrui's cassava grinding machine is simple in structure, reasonable in layout, small in area, simple in operation and convenient in maintenance. It can complete the 3 processes of coarse crushing, fine grinding and pulp-slag separation at one time, and there is no starch color caused by manual production. There is no slag skin, slag block and small matter in the slag. The roller of pulp and cassava grinding machine works with water to shorten the oxidation reaction of raw materials in the air and improve the whiteness of finished starch. The separation rate of slurry and slag in cassava grinding machine above 98% and the residue rate about 2%.

Cassava grinding machine

Cassava grinding machine

These are the 3 types of cassava crushing machine in cassava processing line. For many investors, it is very necessary to choose the right cassava crushing machine. You can contact Doing Holdings - Henan Jinrui Food Engineering Co., Ltd and tell us the process capacity and the quality of finished starch that you need. Doing Holdings - Henan Jinrui's engineers can recommend the suitable cassava grinding machine according to your needs. Also if you are interested in the complete cassava processing line, welcome to contact us.

Want to know more about our products or services? Fill out the contact form below, and we’ll to get back to you and you will get the price list. Please also feel free to contact us by email or phone.( * Denotes a required field).