Blog

2025-09-19

2025-09-19Is your attieke production plagued by low yields? This low yield not only directly impacts profits but also undermines market competitiveness. The key to the problem likely lies with the making equipment. Selecting the right equipment is often crucial for achieving efficient production, improving quality, and increasing efficiency.

Henan Jinrui has been deeply engaged in manufacturing of cassava processing equipment for many years. We understand that fully utilizing every bit of raw material is crucial to your profitability. This article will provide an in-depth analysis from an equipment perspective: how modern attieke making equipment can significantly improve yields, helping you reduce costs, increase revenue, and gain market advantage.

Limited attieke yield

Limited attieke yield

Attieke, a traditional staple food in Côte d'Ivoire, has long relied on manual labor for its processing, a key factor limiting yield improvements. From manual peeling and natural fermentation to traditional grinding, pressing, and air-drying—almost every step involves uncontrollable losses, and the accumulation of these details is quietly eroding your profits.

For example, manual peeling is not only inefficient but also tends to remove too much edible material, resulting in raw material waste. The fermentation process relies on experience, leading to unstable temperature and humidity control, which can lead to inconsistent quality or even spoilage across the entire batch. Inadequate grinding also leaves a large amount of usable starch, further reducing the yield in attieke production. These seemingly "minor" losses can actually reduce your overall attieke yield by 20% or more.

Are you also troubled by the problem of limited attieke yield? In fact, many processors have not yet realized that by optimizing the processing equipment in the key steps of attieke making, these wastes can be effectively reduced and higher benefits can be achieved.

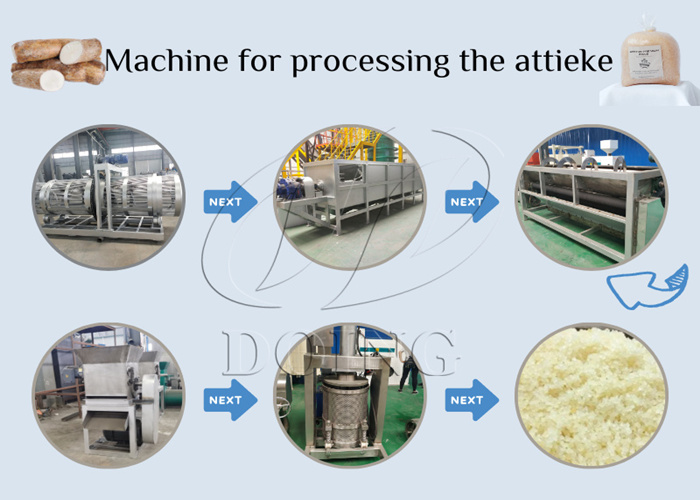

Attieke processing machines

Attieke processing machines

Precise Peeling Maximizes Edible Portion

In attieke making, peeling is the primary step affecting yield. Manual peeling is not only inefficient but also prone to uneven workmanship, resulting in wasted edible material, directly reducing your final attieke yield.

Professional peeling equipment is designed to address this pain point. For example, the sand-roller peeler used made by Henan Jinrui for attieke production uses a flexible friction process to precisely and evenly remove the outermost layer of cassava skin, while maximizing the amount of edible flesh. This meticulous processing significantly improves yield compared to traditional manual methods—actual application data shows it can increase attieke overall output by 5-8%.

Cassava peeling equipment

Cassava peeling equipment

Efficient Grinding Maximizes Cassava Utilization

Traditional attieke production often relies on manual hammering or simple tools for grinding, which not only poses safety risks but also makes it difficult to achieve thorough and uniform crushing. Incomplete grinding means that a large amount of usable cassava fiber and starch remain in the residue, directly reducing the attieke yield.

Modern attieke making equipment is designed to address this bottleneck. For example, the Henan Jinrui cassava grinder utilizes a licker-in crushing structure to achieve more thorough and efficient cassava grinding, eliminating attieke yield losses caused by incomplete grinding.

Cassava grinding equipment in attieke production

Cassava grinding equipment in attieke production

Controlled Fermentation Prevents Unstable Quality

Fermentation is a core process that determines the flavor and quality of attieke. However, traditional methods that rely on natural environments often introduce numerous uncertainties. Temperature and humidity can be unstable, leading to inconsistent fermentation results for the same batch of raw materials. In severe cases, entire batches can even go bad and be scrapped, directly limiting the overall yield of attieke production.

Modern attieke making equipment is equipped with a fermentation system that precisely controls temperature and humidity throughout the fermentation process. This maintains the traditional flavor while significantly improving fermentation success rates and end-product consistency, effectively improving yield.

Usine de fabrication d'attieke

Usine de fabrication d'attieke

Intelligent Drying Reduces Final Losses

Drying, the final, critical step in attieke production, directly impacts the final product quality and yield. Traditional sun-drying methods are prone to uneven drying and mold due to weather fluctuations, resulting in irreparable losses. This not only reduces overall output but can also negate all initial investment.

The intelligent drying system integrated into modern attieke making equipment uses precise temperature control and circulating ventilation technology to provide a continuously stable and ideal environment for the drying process. This system directly helps minimize losses during the drying process and is crucial for improving overall yield.

In short, modern attieke making equipment significantly reduces waste and increases yield by precisely controlling every step of the peeling, grinding, fermentation, and drying process, directly contributing to higher profits for you. Choosing professional attieke making equipment ensures a stable and controllable yield, thus providing the robust production capacity to meet market demands. If you're looking to invest in or upgrade your attieke making equipment, choose Henan Jinrui as your trusted partner. We offer customized equipment solutions to help you build a more productive and profitable attieke production business!

Want to know more about our products or services? Fill out the contact form below, and we’ll to get back to you and you will get the price list. Please also feel free to contact us by email or phone.( * Denotes a required field).