Blog

2025-07-25

2025-07-25Brazil is a leading producer of cassava (mandioca/aipim) and its derivatives, including polvilho (cassava starch, both sweet—polvilho doce—and sour—polvilho azedo). To produce high-quality polvilho, efficient and modern cassava processing machinery is essential. Below are key machinery and steps involved in the process:

1. Cassava Cleaning & Washing Machinery

Purpose: Remove dirt, sand, and leaves.

Machinery:

Dry sieve(for removing soils, mud, and leaves)

Paddle washers (high-capacity water spray systems).

dry sieve

dry sieve

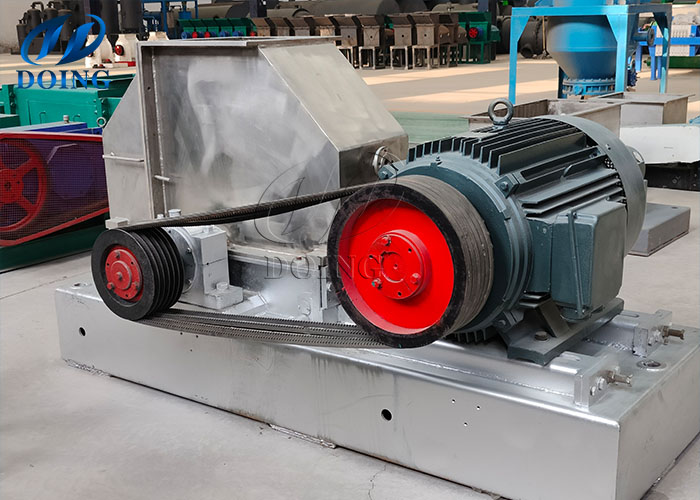

2. Cassava Grating/Rasping Machines

Purpose: Break down cassava roots into pulp for polvilho extraction.

Machinery:

Cassava Cutter ( with durable 4Cr13 rhombus blades for pieces production.)

High-speed raspers (with stainless steel saw blades for fine grating).

cassava rasper

cassava rasper

3. Polvilho Extraction (Sieving& Refining)

Purpose: Separate cassava starch from fibrous pulp.

Machinery:

Centrifugal sieves (for fine filtration of polvilho milk).

Hydrocyclone systems (a unity of concentration, recycle, and refinery for purifying polvilho slurry).

hydrocyclone station

hydrocyclone station

4. Dewatering & Drying

Purpose: Reduce moisture for shelf-stable polvilho.

Machinery:

Peel centrifuges (for dewatering).

Flash dryers (negative pressure drying for getting qualified starch with 12%-14% moisture).

flash dryer

flash dryer

5. Sieving & Packaging

Purpose: Produce fine, uniform polvilho powder.

Machinery:

Sifter Sieve (for fine polvilho powder).

Automatic packaging machines (for 1kg, 5kg, 25kg bags).

Would you like recommendations for small-scale vs. industrial polvilho processing machinery, or details on options for equipment solution in Brazil? If yes, chat with us! Henan Jinrui sells cassava processing machinery to over 120 countries and regions, able to customize production lines with different capacities to you!

Want to know more about our products or services? Fill out the contact form below, and we’ll to get back to you and you will get the price list. Please also feel free to contact us by email or phone.( * Denotes a required field).