Blog

2025-07-04

2025-07-04A common question we receive is: "What is the price of your smallest potato starch production line?" Actually, we, Henan Jinrui, can only offer you a rough price range which changes from $150K to $200k for the final investment depends significantly on the specific configuration which is tailored to your unique requirements. Key factors influencing the final cost of our three-ton-per-hour potato starch production line include:

1. Finished Product Standards: The purity, whiteness, and moisture content you require impact the complexity of refining and drying stages of potato starch production line. The higher requirement on purity, the higher level of equipment configuration, the higher the final price.

2. Technical Requirements: The desired level of automation(semi-automatic or fully automatic), energy efficiency targets, material quality and specific auxiliary equipment needs.

automatic potato starch production line

automatic potato starch production line

3. Raw Material Characteristics: Variations in potato type and soil content can sometimes influence the equipment selection.

Therefore, the precise price of our smallest potato starch production line is determined after thorough discussions between our experienced engineers and your technical team. We, Henan Jinrui, will assess your goals and constraints to provide a customized solution and a transparent, detailed quotation.

Essential Machines in Potato Starch Processing Line

Every stage of the potato starch extraction process relies on specialized machinery. Here are the core components necessary for a functional minimum potato starch processing line:

1. Cleaning Section (Critical for Purity):

Dry Sieve: Removes loose soil, stones, and plant debris.

Gravity Destoner: Efficiently separates heavier stones and clods from potatoes using specific gravity principles.

Rotary Washer: Provides thorough washing with water to remove remaining dirt and surface contaminants.

2. Rasping Section (Liberating the Starch):

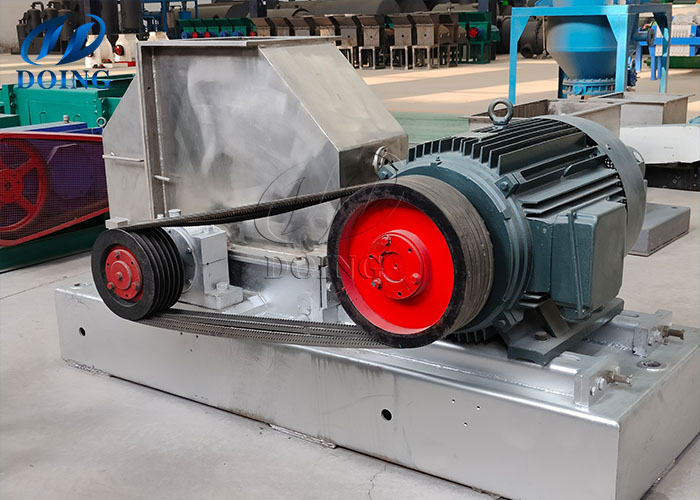

Rasper: High-speed potato starch processing machine that grates the cleaned potatoes into a fine pulp, breaking open cells to release starch granules. This is vital for high starch yield.

potato starch rasper

potato starch rasper

3. Extraction & Screening Section (Separating Starch from Pulp):

Centrifuge Sieve (or Extractor Sieve): Uses centrifugal force to separate the free starch milk (water & starch) from the fibrous potato pulp (potato residue).

4. Refining & Concentration Section (Purifying the Starch Milk):

Hydrocyclone Station: A multi-stage battery of hydrocyclones. This is the heart of purification. It uses centrifugal force in conical chambers to separate starch granules from fine fibers, soluble proteins, and other impurities based on density and particle size, progressively concentrating the starch slurry.

hydrocyclone station

hydrocyclone station

5. Dehydration Section (Removing Excess Water):

Vacuum Filter:Efficiently removes a large portion of the free water from the concentrated starch slurry coming from the hydrocyclones, forming a moist starch cake.

6. Drying Section (Producing Shelf-Stable Starch):

Flash Dryer: The final crucial step. The moist starch cake is instantly dried using hot air in a pneumatic conveying system. This rapid drying preserves starch quality, resulting in a fine, dry powder ready for packaging.

Advantages of Henan Jinrui for Providing Potato Starch Processing Machine

Expert Engineering Team:Our deep technical knowledge ensures your line is optimally designed for your specific potatoes, desired starch quality, and operational goals.

In-House Manufacturing: We control the entire manufacturing process in our modern facility, guaranteeing quality, timely delivery, and seamless integration of all components.

Proven Global Experience: We have successfully designed, manufactured, installed, and commissioned potato starch lines worldwide, from Africa to Southeast Asia and beyond. Our solutions are field-tested.

Do you wanna set up an automatic potato starch production line? If yes, please tell us your requirement, and our professional teams will make a customized production line to you! Chat with our manager and engineer directly!

Want to know more about our products or services? Fill out the contact form below, and we’ll to get back to you and you will get the price list. Please also feel free to contact us by email or phone.( * Denotes a required field).