Blog

2023-12-27

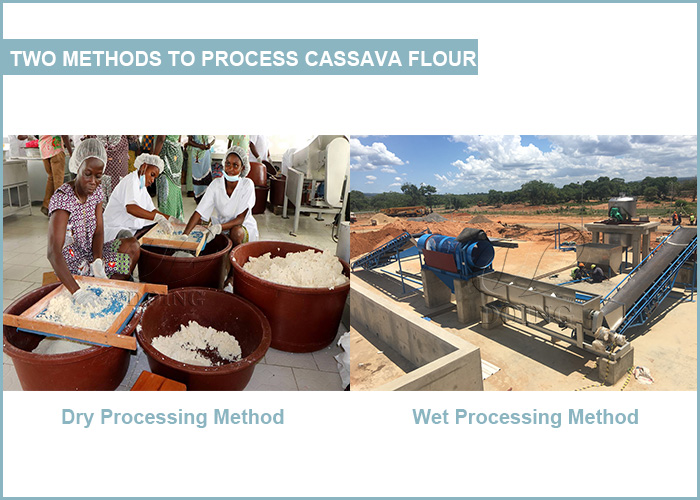

2023-12-27Locally made cassava meal processing machines in Nigeria mainly adopts two processing methods to assistant the production, the cassava meal dry process and wet process. Here is the comparison of the two methods.

The procedures of cassava meal production with dry method:

Locally made cassava meal processing machines in Nigeria, which adopts the dry processing method, has the procedures like that: fresh cassava roots cleaning and peeling, cutting or chipping, drying and milling. Alternatively, some opt to purchase dried cassava chips and use a single cassava milling machine to obtain cassava flour. Although locally made cassava flour machines are inexpensive, their quality and working speed are relatively low. As a result, they are only suitable for small-scale operations and yield poor-quality cassava flour.

The procedures of cassava meal production with wet method:

Locally made cassava meal processing machines in Nigeria use the wet processing method, which involves cleaning, processing, and drying. This method is suitable for large-scale cassava meal processing factories, and offers superior quality and efficiency. The locally made cassava meal wet processing machine in Nigeria can achieve high quality and high yield with its advanced technology.

Cassava meal processing methods

Cassava meal processing methods

The work flow and machines configuration under cassava meal wet process:

Locally made cassava meal processing machines in Nigeria with wet process use feeding hopper, belt conveyor, dry sieve and paddle washer in the cleaning section to reach the cleaning effect. Fresh cassava roots are put into feeding hopper firstly, and then transported by belt conveyor to dry sieve machine. Dry sieve machine will remove impurities attached on cassava roots and then paddle washer will clean cassava completely by using water.

cassava meal machine in Nigeria

cassava meal machine in Nigeria

Then it comes to the processing part. Main cassava meal machines in the section are peeler, cutter, rasper, de-sander, plate-and-frame filter press. The cleaned cassava roots are peeled by peeling machine, and then cut into small pieces by cutting machine. Small pieces of cassava will be sent into rasper machine for crushing and we can get cassava pulp. Cassava pulp will be pumped into de-sander machine to remove sand debris and then pumped into plate-and-frame filter press for dehydration process to get wet cassava cakes.

In the drying part, the cassava meal machines configured are flash dryer, fine miller and sieving machine. The wet cassava cakes will be crushed into wet powder, and then wet cassava powder will be sent into flash dryer. Two stages of dryer are adopted, so that we can get final dried flour with moisture around 12-4%. To ensure high fineness of final flour, fine miller machine is matched to crush dried flour again. Finally sieving machine is installed to sieve coarse flour and get high quality cassava meal as final product.

The above is brief introduction and comparison of locally made cassava meal processing machines in Nigeria. To use wet process technology or dry process technology will depends on production capacity and quality requirement of final flour. If you are going to set up a cassava meal processing factory, welcome to contact us! We, Henan Jinrui, have a branch office and local factory in Nigeria (location: 19B Kudirat Abiola Way Olusosun Bus stop, Ikeja, Lagos, Nigeria), waiting to meet you!

Want to know more about our products or services? Fill out the contact form below, and we’ll to get back to you and you will get the price list. Please also feel free to contact us by email or phone.( * Denotes a required field).