Blog

2025-05-16

2025-05-16Do you know how to choose cassava flour processing equipment? The factors that affect our selection of cassava flour processing equipment mainly include processing method, capacity, automation level, and equipment quality. Here, Henan Jinrui will explain the factors that affect the selection one by one, which will facilitate your better selection of cassava flour processing equipment.

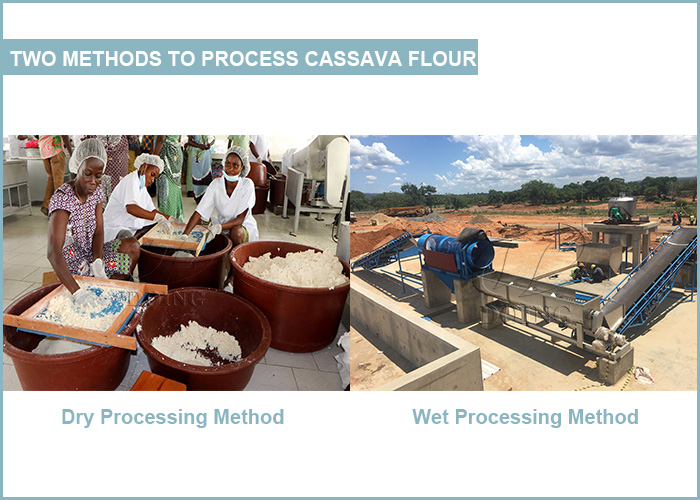

Before choosing the cassava flour processing equipment, we should decide which processing method will be pick: dry method or wet method? The different processing methods correspond to the selection of different cassava flour processing equipment.

Two methods to process cassava flour

Two methods to process cassava flour

Dry Method to process cassava flour is simpler and more cost-effective for initial investment. It involves cleaning, peeling, slicing, drying, milling, sieving, and packing. The equipment needed includes a dry sieve, paddle washer, cassava peeler, slicer, hot-air dryer, hammer mill, sifter, and packing machine. And wet processing method for cassava flour production is more hygienic and produces finer flour. It includes washing, peeling, grating, dewatering, drying, sieving, and packing. The processing equipment required includes a dry sieve, paddle washer, cassava peeler, cutting machine, rasper, plate-frame filter press, flash dryer, sifter, and packing machine.

So one of the important factors influencing your selection of cassava flour processing equipment is the processing method. Henan Jinrui offers both types of processing equipment, tailored to meet the specific needs of your production goals.

The capacity is also the main factor should be considered when choosing the cassava flour processing equipment. The different equipment configuration and price varies based on the capacity.

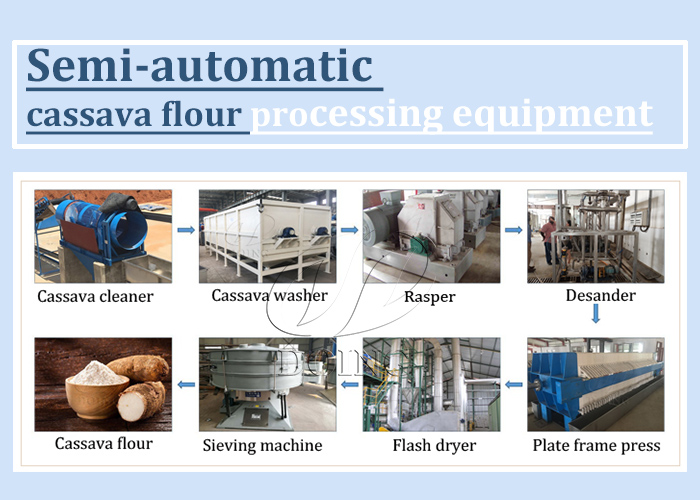

Cassava flour processing machines

Cassava flour processing machines

Small-scale production, with relatively low investment, is suitable for new starters or small-scale producers, Henan Jinrui recommends starting with essential machines such as a peeling machine, grinding machine, dewatering machine, and drying machine. These processing equipment can be scaled up later as your business grows. For larger operations, Henan Jinrui offers fully automated cassava flour production lines with higher capacity machines, including feed hoppers, belt conveyors, and more advanced dewatering and drying systems, which need the larger budget.

The capacity of your cassava flour processing equipment should match your production goals and budget during choosing processing equipment. Henan Jinrui can provide a range of equipment options to suit different scales of operation.

The automation level of your processing equipment directly impacts the quality and yield of the cassava flour. Therefore, the automation level also should be considered when we select the cassava flour processing equipment.

Cassava flour production line

Cassava flour production line

Manual or semi-automatic cassava flour processing equipment has lower prices, but higher labor costs and poor quality of cassava flour. For example, traditional methods of drying cassava flour include sun drying or electric drying rooms, which require manual operation, take longer to dry and also affect the final quality of cassava flour. The fully automatic cassava flour processing equipment has PLC control, sensors, and real-time monitoring functions, which can reduce labor costs, increase the production efficiency and enhance the quality.

The performance and quality of cassava flour processing equipment is a critical factor in its selection. Unstable and poor quality equipment can lead to frequent breakdowns, which in turn can disrupt production schedules, increase maintenance costs, and reduce overall productivity. When choosing processing equipment, look for machines that have a reputation for stability and reliability. For example, compared with carbon steel, cassava flour processing equipment made of food-grade stainless steel is more popular among customers because of its corrosion resistance and durability.

Cassava flour making line

Cassava flour making line

In summary, the main factors affecting the selection of cassava flour processing equipment are processing method, capacity, automation level, and equipment quality. Henan Jinrui, with over 10 year experience in manufacturing and supplying cassava flour processing equipment, can offer customized solutions to help you balance initial investments with long-term efficiency, maintenance, and scalability to maximize returns. If you have any demand for cassava flour processing, welcome to contact us!

Prev: Nothing

Want to know more about our products or services? Fill out the contact form below, and we’ll to get back to you and you will get the price list. Please also feel free to contact us by email or phone.( * Denotes a required field).