Blog

2025-12-03

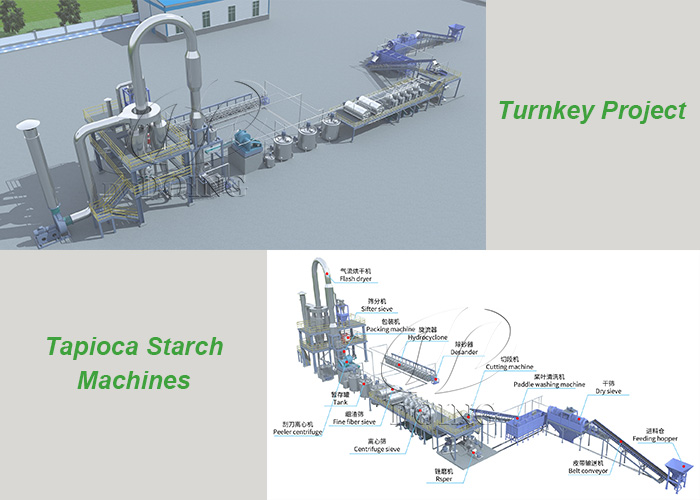

2025-12-03A cassava starch processing turnkey project is a comprehensive package where a single provider—like us—takes full responsibility for designing, supplying, installing, and commissioning your entire plant. Think of it as receiving the keys to a fully built, tested, and ready-to-run factory. Henan Jinrui, as your partner in this venture, provide more than just machines; we deliver a complete, operational solution.

cassava starch turnkey project

cassava starch turnkey project

The Core Parts of Our Cassava Starch Turnkey Project

Understanding the components of this turnkey solution is key. A successful cassva starch processing project is built on several integrated pillars:

In-Depth Feasibility & Customized Plant Design: We start not with a sales catalog, but with an analysis. Our engineers assess your local cassava variety, starch content, target capacity, and site conditions. This data informs a customized plant layout and process flow designed specifically for food-grade starch output, ensuring optimal yield and purity from day one.

Supply of Complete Processing Machinery: This is the heart of the cassava starch processing project. We provide the full equipment chain, meticulously selected for compatibility and performance:

cassava starch turkey project

cassava starch turkey project

Cassava Cleaning & Washing Unit: To remove soil, sand, and peel, ensuring feedstock purity.

Cassava Rasping/Grinding Machine: For maximum starch cell rupture and high extraction rates.

Cassava Starch Separation & Refining System: Including centrifugal sieves, hydrocyclone stations, and de-sanding cyclones to separate fine fiber, cell sap, and impurities, achieving the brilliant white color required for food-grade starch.

hydrocyclone station

hydrocyclone station

Cassava Starch Dehydration & Drying Machines: Efficient peeler centrifuges and flash dryers to gently remove moisture without degrading starch quality.

Sieving & Automated Packaging: To produce a uniform cassava starch powder and package it for market.

Professional Installation, Commissioning & Training: Our expert technicians oversee the entire installation, ensuring every cassava starch processing machine is perfectly aligned and integrated. We then conduct rigorous commissioning, running the plant with your cassava to fine-tune performance and guarantee it meets all design specifications. Crucially, we provide comprehensive hands-on training for your operational and maintenance team, empowering them to run the plant confidently.

After-Sales Support & Optimization: Our partnership continues long after startup. We offer reliable spare parts supply, remote technical support, and periodic maintenance services. We are invested in your long-term productivity and are available to help you optimize processes or plan for future capacity expansion.

Why Choose a Turnkey Solution for Cassava Starch Production?

Choosing a fragmented, piecemeal cassava starch processing equipment purchase from multiple vendors carries hidden risks: compatibility issues, finger-pointing when problems arise, and costly project delays. Our cassava starch turnkey project eliminates these pitfalls by providing:

Single-Point Accountability: One contract, one responsible partner for the entire system's performance.

Time and Cost Certainty: Streamlined project management prevents budget overruns and accelerates your time-to-market.

Guaranteed Process Integrity: We ensure all cassava starch turnkey project parts work in perfect harmony to deliver the consistent food-grade quality your customers demand.

Peace of Mind: You can focus on your core business—sourcing raw materials and building your market—while we handle the technical complexities.

Embarking on a cassava starch processing turnkey project is a significant investment. By opting for a professional turnkey solution, you are not just buying machinery; you are investing in a guaranteed path to success. Ready to transform your cassava? Contact us today for a detailed consultation!

Want to know more about our products or services? Fill out the contact form below, and we’ll to get back to you and you will get the price list. Please also feel free to contact us by email or phone.( * Denotes a required field).