Blog

2021-08-18

2021-08-18As we know, cassava roots is fit in extracting the cassava starch because it has a high content of cassava starch. The cassava starch business always has a decent market in recent years. So, more and more people are glad to be engaged in this business. Then, how to extract the cassava starch? Actually, the cassavastarchproductionprocess includes 7 parts: cleaning, washing, crushing, separating, concentrating, dehydrating and drying. Next is the detailed introduction:

Workflow of cassava starch processing machine

Workflow of cassava starch processing machine

Cleaning your cassava roots

You should remove excessive impurities in your raw materials by using the dry sieve. The main impurities includes leaves, dirt, stones and ropes, etc.

Washing your cassava roots

Next, you need to use the paddle washing machine to clean up the sand and mud attached to the cassava roots. Then, the clean cassava roots are transformed to crushing station.

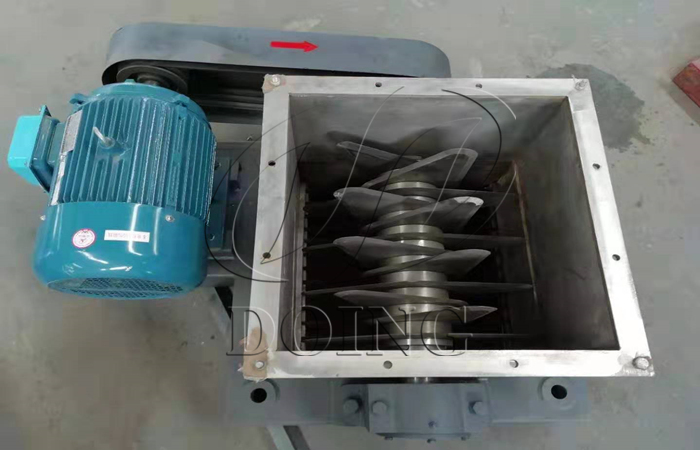

Crushing these roots

The crushing station aims to cut the cassava roots into smaller pieces and crush these pieces into cassava starch slurry.

Cutting machine

Cutting machine

Separating the fiber and starch slurry

In this step, the centrifuge sieve aims to separate the fiber and starch slurry, and separate the smaller fiber by using the fine fiber sieve further.

Extracting cassavastarchmilk

Then the hydrocyclone machine is used to remove the protein, fiber and cell sap in the starch milk to get scrubbing starch milk.

Dehydrating the cassavastarchmilk

The extracted cassavastarchmilk needs to be dehydrated. The machine used in this step is a peeling centrifuge, which adopts continuous operation and intermittent discharging to complete the dehydrate process. The moisture content can be decreased to 36.5%

Peeler centrifuge

Peeler centrifuge

Drying the the cassavastarchmilk

Lastly, you need to use the flash fryer to make the cassava starch dry. Jinrui Company’s negative pressure cooling system of the flash dryer can not only dry the cassava starch, but can ensure even moisture in the finished cassava starch.

Recommended reading : cassava starch processing machine

In short, the above automated cassava starch production process has the advantages of high processing efficiency and high starch extraction yield rate. Henan Jinrui Company has been committed to manufacture and supply the cassava starch processing machine for more than 10 years. We are glade to guide you how to extract cassava starch from cassava roots with cassava starch processing machine.

Want to know more about our products or services? Fill out the contact form below, and we’ll to get back to you and you will get the price list. Please also feel free to contact us by email or phone.( * Denotes a required field).