Blog

2020-01-11

2020-01-11Cassava starch has wide application in food and non-food industries. Therefore more and more business men want to invest starch production factory in Africa. Mostly they will start with small scale cassava starch processing plant and then scale up in years.

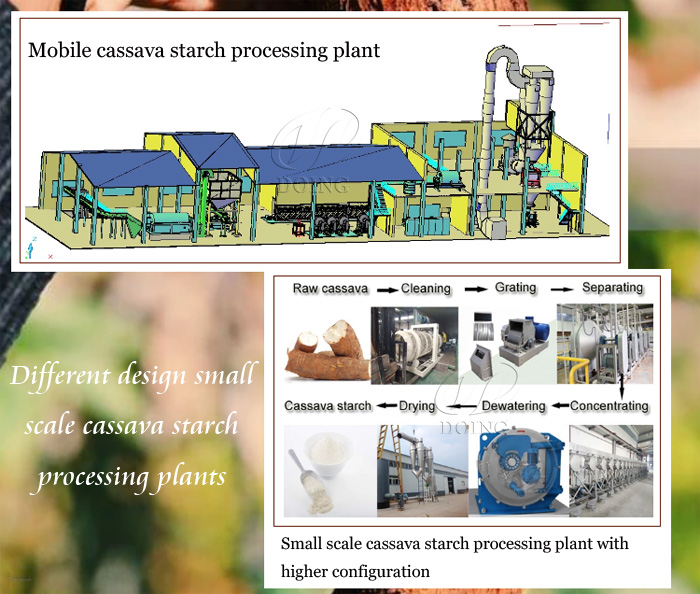

Small scale cassava starch processing plant is small in capacity but has complete procedures as cleaning, washing, crushing, sieving, starch refining, dehydrating and drying. It can reduce investment budget at start, and is very popular by investors. We have two designs for small scale cassava starch processing plant, one is basic configuration which can meet people’s fundamental needs for starch production, another is relatively higher configuration which can ensure high quality cassava starch.

Different design small scale cassava starch processing plants

Different design small scale cassava starch processing plants

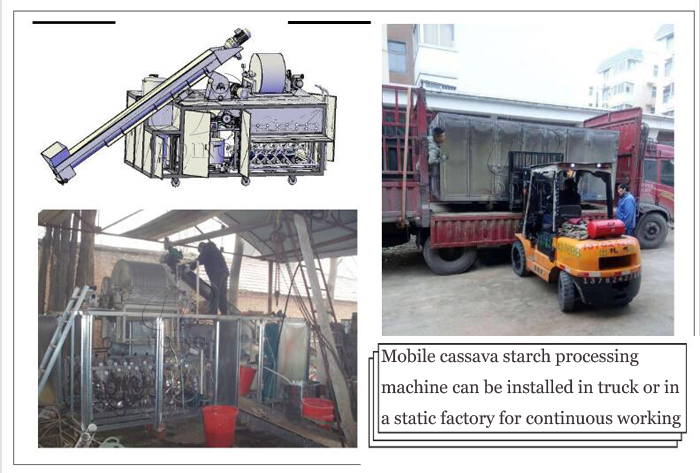

Mobile cassava starch processing machine is new design equipment which can meet client’s requirement to start starch production with lowest investment. The plant includes starch extraction, dehydration and drying sections. Starch extraction section is combined into all-in-one machine, which achieve that all machines from cleaning, washing, crushing, sieving and refining are loaded in a mobile rack. The mobile starch extraction section can be transported in truck to anywhere raw material is available. Refined starch slurry can be collected in barrels and sent to processing center for dehydration and drying. You can also put all machines in a static factory and make the whole line work continuously.

Mobile cassava starch processing plant

Mobile cassava starch processing plant

Another design for small scale cassava starch processing plant has higher configuration and can produce higher quality starch. The whole line can be divided into three sections: cleaning section, processing section and drying section. In cleaning section, raw cassava tubers are well cleaned and surface skins are removed through dry sieve and paddle washing machine. In processing section, which is also called starch extraction section, consists of crushing, sieving, and refining procedures. Cutting machine and rasper are used to crush cassava completely to make starch particles released as much as possible. Then solid fibers are separated by centrifuge sieve and liquid protein and fats are removed by hydrocyclone station. Finally in drying section, water is dehydrated and we can get high quality starch with moisture content 10-14%.

If you want to start cassava business with small scale cassava starch processing plant, welcome to contact us, and our project manager will give you reasonable proposal based on your requirements and situation.

Want to know more about our products or services? Fill out the contact form below, and we’ll to get back to you and you will get the price list. Please also feel free to contact us by email or phone.( * Denotes a required field).