Blog

2025-12-26

2025-12-26Lafun flour is a unique West African staple made from fermented cassava. Unlike regular cassava flour, it has a mild sour taste and is used to make smooth, satisfying dishes like Amala, Lafun. If you’re looking to produce it efficiently, understanding the process and the right cassava processing machines is key.

Here’s a simple, step-by-step guide from Henan Jinrui on how to make lafun flour from cassava, with the essential equipment for each stage.

Lafun flour processing line

Lafun flour processing line

The lafun flour process begins with fresh cassava roots. To ensure a clean, safe, and high-quality end product, thorough washing and peeling are essential. First, roots are fed into a paddle washing machine where rotating paddles and water scrub away all dirt and soil. Immediately after, they move to a peeling machine. Efficient peelers, like those from Henan Jinrui, use abrasive rollers and water sprays to remove the skin completely with minimal flesh loss. This high peeling rate is crucial for lafun flour production, as it directly affects the purity, whiteness, and consistent fermentation of the final flour.

Once peeled, the cassava roots need to be crused. A cassava grating machine crushes them into a fine, wet mash. This step is crucial for effective fermentation later. Using a durable grater, such as the grinders provided by Henan Jinrui, up to 90% grinding rate, ensures a consistent texture that is ideal for the next stages of lafun flour production.

Cassava processing machine for lafun flour production

Cassava processing machine for lafun flour production

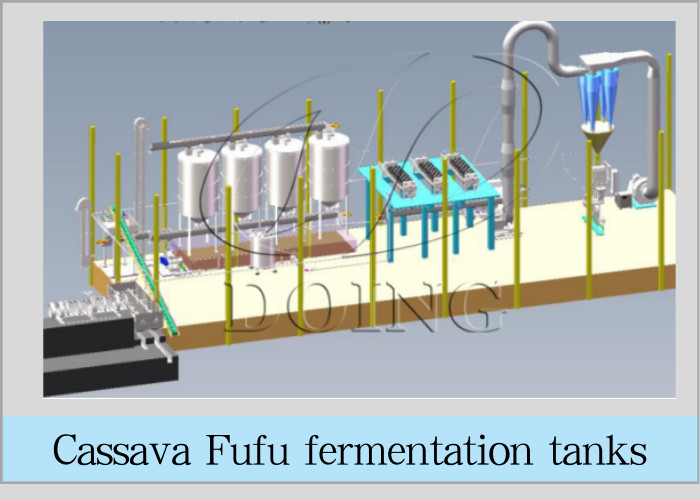

This is what makes lafun special. The grated mash is transferred to fermentation tanks or pits, where it soaks in water for 2 to 4 days. While this is a natural process, using proper, hygienic tanks helps control the fermentation, giving lafun flour its characteristic mild sour taste and improving its shelf life.

After fermentation, the cassava mash is very wet, the dehydration process is necessary for lafun flour production. A hydraulic dewatering press or a screw press is used here. It applies strong, even pressure to squeeze out the water, forming a firm cassava cake. An efficient press, like Henan Jinrui's hydraulic press, maximizes water removal, which significantly cuts down on drying time and fuel costs later.

Lafun flour making line

Lafun flour making line

The pressed cassava cake needs to be crushed and dried to produce lafun flour. The dehydrated cassava pieces are fed into a milling machine and ground into a fine powder. It then enters a flash dryer, which uses hot air to quickly and evenly reduce the moisture content to a stable level (approximately 12-14%), resulting in high-quality lafun flour.

To ensure the consistent, smooth quality expected of lafun flour, the milled powder is then passed through a sieving machine. This process removes any coarse particles, guaranteeing the final lafun flour is uniformly fine. Finally, the finished lafun flour moves to an automatic packaging machine for accurate weighing and hygienic sealing into bags.

Henan Jinrui cassava lafun flour machine

Henan Jinrui cassava lafun flour machine

As you can see, how to make lafun flour from cassava depends on a clear process and reliable cassava processing machines at every step. Investing in the right equipment directly impacts the product's quality, production speed, and profit.

If you’re planning to start or upgrade your lafun flour production, Henan Jinrui can provide the complete processing line—from washers and peelers to presses, dryers, and mills. Contact us today to get a customized equipment solution!

Want to know more about our products or services? Fill out the contact form below, and we’ll to get back to you and you will get the price list. Please also feel free to contact us by email or phone.( * Denotes a required field).