Blog

2025-12-24

2025-12-24For cassava processing, the drying stage impacts the final product's moisture content, texture, shelf life, and market value. The market offers several types of cassava dryers, each engineered for specific products and scales. This article will introduce the primary options available and provide a clear framework to help you make an informed decision.

Here’s a concise look at the common cassava dryers in the cassava processing industry:

Flash Dryer: It is the industry-preferred cassava drying machine for producing high-quality starch and flour. It operates on a principle of instantaneous drying, where wet starch cake is dispersed and dried within 1-2 seconds in a stream of hot air. This ultra-short processing time is its key advantage, as it preserves the starch's vital functional properties—preventing gelatinization and ensuring high brightness and a fine, consistent powder. Beyond superior product quality, the cassava flash dryer offers high thermal efficiency, a compact vertical footprint, and seamless integration into automated processing lines. For clients focused on premium cassava starch for food, paper, or textile markets, this dryer is an essential investment for achieving competitive, market-ready quality efficiently and at scale.

cassava starch flash dryer

cassava starch flash dryer

Rotary Drum Dryer: These are the robust, high-capacity champions for bulk drying. Featuring a large rotating cylinder, they are perfect for continuously drying cassava chips destined for animal feed or ethanol production. Their advantages include high throughput, durability, and tolerance for variable feed moisture. They are the go-to choice for large-scale chip producers and feed mills.

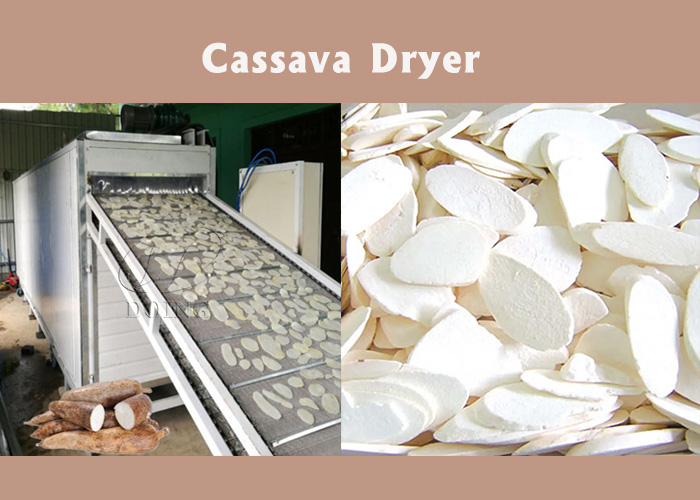

Belt Dryer (Multi-Conveyor Dryer): Operating on a series of slow-moving mesh belts within an enclosed heat chamber, these dryers excel at gentle, uniform drying. They are ideal for products where precise temperature control and minimal breakage are paramount, such as premium-grade fermented cassava pieces or certain flours. Clients are typically medium-to-large processors targeting high-value food markets where perfect product appearance is key.

belt dryer

belt dryer

Cabinet/Tray Dryer: Essentially industrial-sized oven cabinets, these are batch processors where product is spread on trays. They offer low initial cost and great flexibility for testing or small-batch production of various products. Their main advantage is accessibility for startups, but they are labor-intensive and inconsistent for commercial-scale output. They serve small entrepreneurs, research institutes, and pilot plants.

Henan Jinrui can recommend you the most suitable cassava drying machine based on your budget and capacity. If you wanna engage in cassava processing and purchase cassava machines, you can chat with us! We will send you the specifications and solutions!

Want to know more about our products or services? Fill out the contact form below, and we’ll to get back to you and you will get the price list. Please also feel free to contact us by email or phone.( * Denotes a required field).