Blog

2025-12-12

2025-12-12Among the many delicacies of Africa, fufu stands out for its unique soft and creamy texture. However, the traditional fufu production relies heavily on strenuous physical labor, involving tedious and inefficient steps, which has become a major bottleneck restricting its large-scale production and market expansion.

To address this challenge, Henan Jinrui, a professional cassava processing equipment manufacturer, will provide a detailed analysis of how to modernize the production process and overcome limitations in capacity and scale by utilizing a highly efficient and reliable fufu-making machine.

Fufu making machine

Fufu making machine

Traditional fufu making involves boiling starchy crops like cassava, plantains, or yams, then pounding them in a mortar with a pestle until a smooth, elastic texture is achieved. While this manual method works well in home kitchens, it faces significant limitations in modern production and is unsuitable for large-scale food manufacturing. Reliant on strenuous pounding and skilled labor, the process is inherently slow, inconsistent in quality, and difficult to scale—posing challenges to commercial growth and food safety compliance.

Employing reliable fufu making machine is the fundamental solution to overcoming the limitations of traditional manual methods and achieving truly modern production. Henan Jinrui presents two efficient mechanized pathways, enabling you to choose the most suitable modern production model based on your specific goals—each centered around a reliable fufu making machine.

Fufu making machinery

Fufu making machinery

This approach is designed for producers who aim to retain the authentic texture and taste of traditional fufu while achieving commercial scalability. By integrating a streamlined equipment line, it systematically automates each stage of the classic process—from washing and peeling to cooking, pounding, and kneading—ensuring both efficiency and consistency.

The production begins with efficient raw material preparation. Utilizing reliable cassava washing and peeling equipment, such as Henan Jinrui’s high-capacity peeler capable of processing over 700 kg per hour, ensures a continuous supply of clean, peel-free cassava. Once steamed, the cassava moves to the core of this modern production line: an automatic fufu pounding machine. This reliable fufu making machine accurately replicates the rhythmic pressing and folding of manual pounding, transforming steamed cassava into smooth, elastic dough—batch after batch, with uniform quality.

Through this integrated setup, producers can significantly increase output, enhance food safety, and maintain the cherished traditional texture, achieving a seamless blend of heritage and modern efficiency.

Fufu powder making line

Fufu powder making line

For producers targeting wider distribution, longer shelf life, and maximum scalability, the flour-based approach represents the most strategic form of modern production. This method separates the fufu making into two optimized phases: large-scale flour production and flexible final preparation.

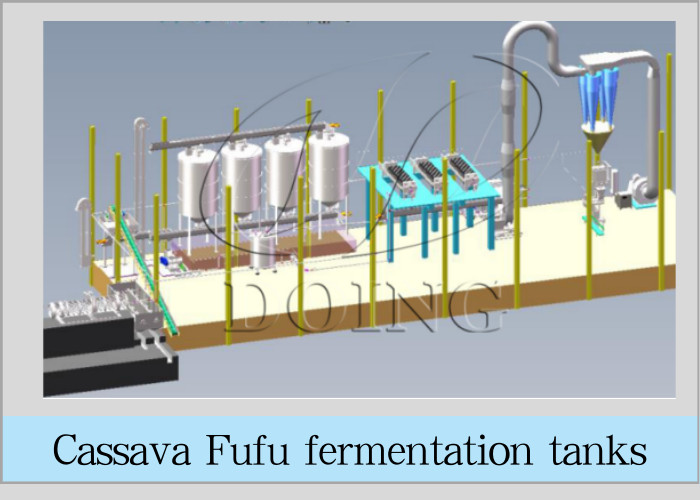

The first phase focuses on creating a stable, storable base product: high-quality fufu flour. This is achieved through Henan Jinrui’s integrated cassava processing line, which automates the complete workflow—cleaning, peeling, grating, dewatering, drying, and milling—transforming fresh cassava into uniform, fine flour with extended shelf stability. This flour becomes a versatile and transportable raw material, ideal for storage and logistics.

The second stage converts flour into ready-to-eat fufu using industrial mixers and cookers. These systems ensure precise hydration, steaming, and kneading, delivering batch-after-batch consistency in texture and taste. By adopting this two-stage modern production model, businesses gain unmatched operational flexibility, ease of packaging, and the ability to supply consistent quality to retail and export markets—all powered by reliable fufu making machine that ensures efficiency at scale.

Whether you aim to preserve authentic texture via fresh cassava processing or prioritize scale with flour-based production, modernizing your operation with a reliable fufu making machine is essential to overcome capacity constraints and expand your market reach.

Ready to modernize your fufu production? Contact Henan Jinrui today for a free consultation and a customized equipment solution designed to scale your business.

Want to know more about our products or services? Fill out the contact form below, and we’ll to get back to you and you will get the price list. Please also feel free to contact us by email or phone.( * Denotes a required field).