Blog

2025-05-07

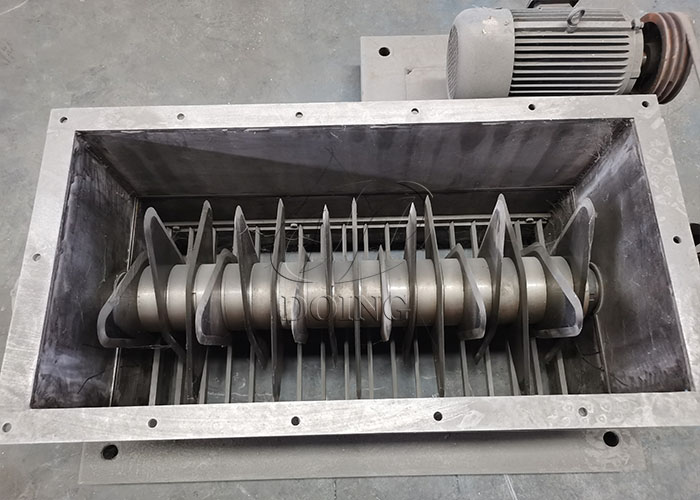

2025-05-07In starch processing plants, the cassava rasper (also known as a grinding machine) plays a critical role in maximizing starch yield. By rotating saw blades at high speeds, the cassava rasper ruptures cassava root cell walls, releasing bound starch granules and improving extraction efficiency. However, the intense mechanical friction and abrasive nature of raw materials subject the cassava rasping equipment to significant wear and tear. This article explores the wearing parts of cassava rasper and the ways to prolong its operational lifespan.

What is the wearing part of cassava rasper?

What is the wearing part of cassava rasper?

Question: What is the wearing parts of cassava rasper?

saw blade

saw blade

Answer:The saw blade stands out the most vulnerable wearing part of cassava rasper.

Analysis: The intense mechanical friction and abrasive nature of raw materials subject the cassava rasper to significant wear and tear.

Firstly, abrasive wear. Cassava roots contain fibrous materials and sand particles that gradually create uneven stress distribution on blades, eroding the blade edges of cassava rasper; secondly, impact damage. Metal debris (e.g., nails, stones) or oversized root chunks collide with high-speed blades, causing sudden blade chipping or cracking.

How to extend the lifespan of saw blades of cassava rasper?

Given that frequent blade replacement not only increases maintenance costs but also disrupts the production continuity of cassava starch. To mitigate these issues, Henan Jinrui, a professional supplier of cassava processing machinery for over 10 years, here will offer you two targeted engineering solutions.

1. Install a Demagnetizer(Metal Detector)

metal detector

metal detector

This device uses magnetic fields to adsorb and remove ferrous impurities from raw materials before they enter cassava rasper.

Benefits:

Reduces blade impacts from metal debris by over 90%.

Prevents micro-cracks in blades, extending service life.

Lowers unplanned downtime caused by blade failures.

2. Add a Pre-Crusher (Cassava Cutting Machine)

cassava cutting machine

cassava cutting machine

Deploy a pre-crusher upstream of cassava rasper to shred raw cassava into smaller, uniform fragments (e.g., 2–5 cm).

Benefits:

Ensures smoother feeding into cassava rasper, minimizing blade vibration.

Reduces blade workload by eliminating oversized materials.

Enhances cassava starch release efficiency due to better cell wall exposure.

The wearing part of cassava rasper is saw blade and the lifespan of its saw blades hinges on proactive contamination control and mechanical optimization. By integrating demagnetizers and cassava cutting machine, you can prolong the lifespan. Henan Jinrui can provide all these cassava processing machine and automatic cassava starch production line. If you have interest, we are glad to show you the project working sites!

Want to know more about our products or services? Fill out the contact form below, and we’ll to get back to you and you will get the price list. Please also feel free to contact us by email or phone.( * Denotes a required field).