Blog

2023-11-22

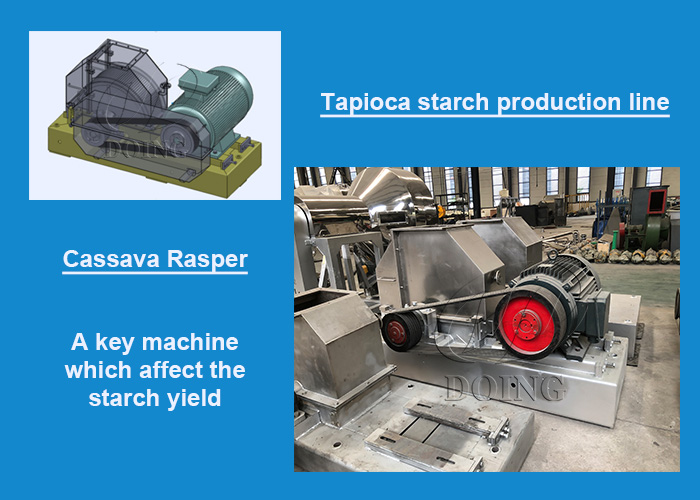

2023-11-22Cassava Rasper has revolutionized the production of fufu flour and tapioca starch. These two cassava products have gained popularity in recent years, with a growing market demand. In Africa, fufu flour has become a viable alternative to wheat flour, while tapioca starch finds various applications in industries such as beer and paper production. As more and more people seek to learn about the processing of these products, the cassava rasper has emerged as a crucial piece of equipment intended for processing fufu flour and tapioca starch.

Cassava rasper intended for fufu flour production

Cassava rasper intended for fufu flour production

The process for cassava rasper to process fufu flour and tapioca starch involves transforming fresh cassava tubers into the cassava slurry. After cleaning the tubers, they need to be grated, and this is where the cassava rasper comes into play. While there are other grating machines available in the market, such as the hammer mill and roller grating machine, the cassava rasper stands out as the most advanced option. It boasts a grating rate of over 96%, surpassing other machines in terms of efficiency. This high grating rate ensures that a significant amount of starch can be extracted from the cassava tubers, resulting in a high-quality final product.

Cassava rasper intended for tapioca production

Cassava rasper intended for tapioca production

The cassava rasper installed in the fufu flour production lines and tapioca starch processing line, with its rotor and blades, grates the cassava tubers at a speed of over 2000 rpm per minute. The bottom net of the machine has a 2mm opening, ensuring that the grated slurry is less than 2mm in size before it passes through the net to the next step. Given the long and large size of cassava tubers, a cutting machine is used to first cut them into smaller pieces before they are processed by the rasper machine. What’s more, the cassava rasper is equipped with durable components, such as Sweden bearings and German Opit belts, ensuring its longevity. Additionally, a magnet device is installed before the rasper to prevent any metal from entering the processing system.

The technology behind the cassava rasper originated in Europe and has proven to be highly effective in fufu flour and tapoioca cassava processing. We, Henan Jinrui, can customize the cassava rasper according to the specific requirements of our clients. In addition to fufu flour and tapioca starch processing, we also offer machines for the production of garri, potato starch, and sweet potato starch. If you are interested in any of these processing options, we welcome your inquiries and are ready to provide our expert advice.

Want to know more about our products or services? Fill out the contact form below, and we’ll to get back to you and you will get the price list. Please also feel free to contact us by email or phone.( * Denotes a required field).