Blog

2021-01-05

2021-01-05Starch has become one of the main value-added products of cassava processing. Do you know the preparation process of starch from cassava? Here are the details.

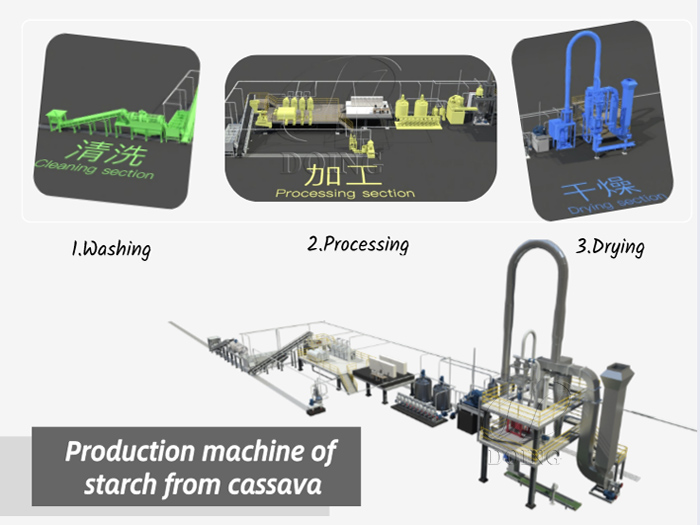

The main preparation process of starch from cassava can be summarized into 4 sections. It includes cassava cleaning and washing process, crushing and extraction process, separating and concentration process, and drying and packaging process.

1. The cassava cleaning and washing process:

The cassava cleaning and washing process is the first step in the the preparation process of starch from cassava. It is mainly to remove the dirty and the outer skin of cassava. The cleaning process is divided into two-stage cleaning. Dry sieve and paddle washing machine is used for it.

Specific workflow:

- The fresh cassava roots are send to the dry sieve through a conveyor belt to remove stones, leaves, branches and other large impurities.

- After entering the paddle washing machine, under the action of the stirring paddle in the paddle washing tank, the cassava rubs against each other to remove the skin and sediment. Countercurrent washing principle is adopted which has a good cleaning effect;

2. Crushing and extraction process

Starch is stored in cassava root cells and needs to be crushed to obtain it. Crushing is the operation process of crushing a large solid materials into suitable or fine starch by means of external force. Currently, cassava cutter and rasper machine are commonly used for crushing.

Specific workflow:

- Use a cutting machine to pre-crush the cassava and crush it into a 3-5 cm pieces.

- Use rasper machine to fully crush the cassava to obtain starch slurry. The rasper machine can fully open the cell wall of cassava and turn the bound starch into free starch which can ensure a high starch extraction rate.

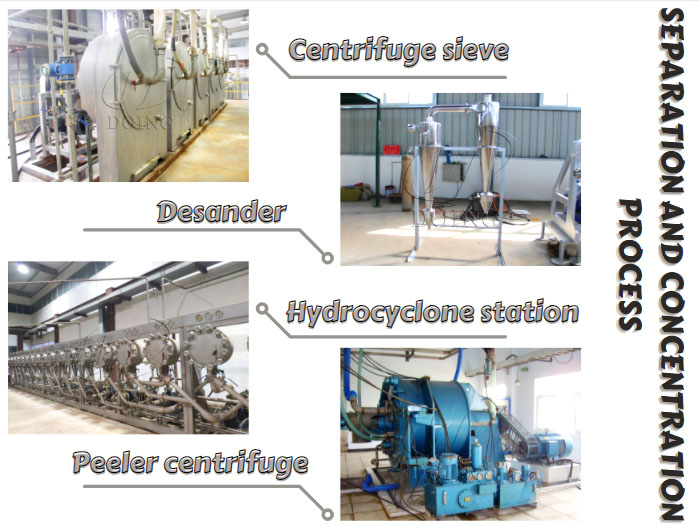

3. Separation and concentration process

The separating and concentration process is one of the important sections in the preparation process of starch from cassava. The main cassava starch processing equipment of this section includes centrifuge sieve, desander, hydrocyclone station and peeler centrifuge machine.

After crushing, the starch slurry is pumped to the separation section where the starch is separated from fibers. After sieving the fiber, it is de-sanding. And then the hydrocyclone station will wash and concentrate the starch slurry to remove cell fluid, fat, protein, etc,. The water content of concentrated starch slurry is about 80%-85%. Therefore, it needs to be dehydrated by a peeler centrifuge to reduce the moisture content to less than 40%, which will save the cost of drying.

Specific workflow:

- After crushing, starch slurry is transported to the centrifuge sieve by a pressure pump for primary separation to filter fiber.

- After separation and filtration, the slurry is pumped to the desander for desanding operation.

- After sand removal, the slurry is pumped to the peeler centrifuge for dehydration.

4. Drying and packaging process

The concentrated starch is conveyed to the drying system by the screw conveyor to keep the water content of the starch product at 12%~13%. In order to avoid the loss of starch, the drying system is equipped with a special cyclone separation device to recover the starch. The drying and packaging process includes flash drying machine and automatic packaging machine.

Specific workflow:

- The flash dryer is negative press drying to evaporate surface moisture instantaneously.

- After drying, the cassava starch is pumped to the feeding port of the packaging machine which can automatically complete the packaging process.

The preparation process of starch from cassava will influence the quality of final cassava starch. So you had better choose the processing technology with reasonableness, stability and advancement. Doing company is committed to the continuous upgrading the machine production technology. We believe we can provide efficient and high-quality cassava starch processing machine for you. If you need, welcome to contact us.

Want to know more about our products or services? Fill out the contact form below, and we’ll to get back to you and you will get the price list. Please also feel free to contact us by email or phone.( * Denotes a required field).