Blog

2023-10-13

2023-10-13Pea starch has a white color, high transparency, good flexibility, and film-forming properties. It is widely used in food production, and beneficial to the human body.

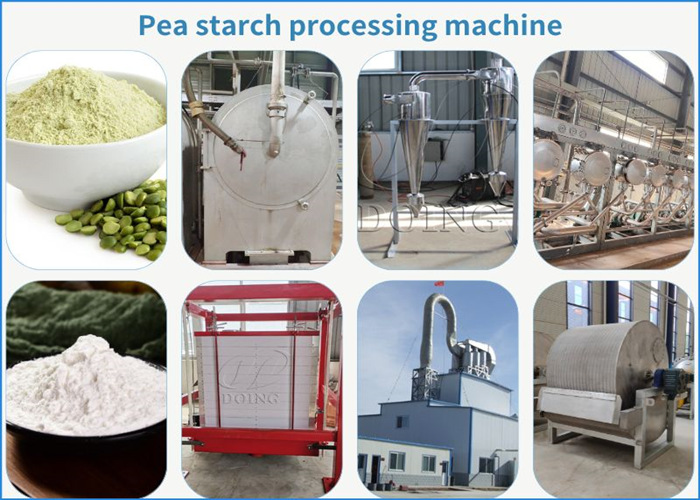

Henan Jinrui company can supply machines for pea starch production from pea flour. The process of making pea starch is pea flour slurry making, steeping, fiber separation, de-sanding, starch slurry refining, dewatering, drying, sieving, and packaging.

Pea starch production from pea flour

Pea starch production from pea flour

Pea starch processing machines include centrifuge sieve machines, de-sander machines, hydrocyclone stations, vacuum filter machines, flash dryers and sieving machines.

The process of the Pea starch processing machine

Firstly mix pea flour with water to make a slurry. And put the slurry into a tank for steeping.

After steeping, starch can be released, and the next is to separate different foreign contents to get starch.

Centrifuge sieve machines of pea starch processing machines are used for fiber separation. To ensure a good separation effect, we will normally match 4-5 stages of sieving, reducing starch lost in fibers. After that, a de-sander machine is used to eliminate small impurities.

Pea starch processing machines

Pea starch processing machines

After fibers sieving and sand removal, the next is starch slurry concentration and refining. To ensure high quality of final pea starch and high starch yield, 12-18 stages of hydrocyclone station will be installed.

We will get high-quality and purified pea starch slurry from the hydrocyclone station. Then pea starch slurry will be pumped into a vacuum filter machine for starch dehydration. After dewatering, we can get wet pea starch with a moisture content of around 40%.

The last step of pea starch production is drying and sieving. Wet pea starch powder will be sent into the flash dryer for the final drying process, and then a sieving machine is applied to separate coarse pea starch powder from which we can get high quality pea starch that can be stored or sold to market directly.

The above is a brief introduction to pea starch production from pea flour. If you have any requirements for our pea starch processing machine, feel free to contact us any time.

Want to know more about our products or services? Fill out the contact form below, and we’ll to get back to you and you will get the price list. Please also feel free to contact us by email or phone.( * Denotes a required field).