Blog

2023-10-07

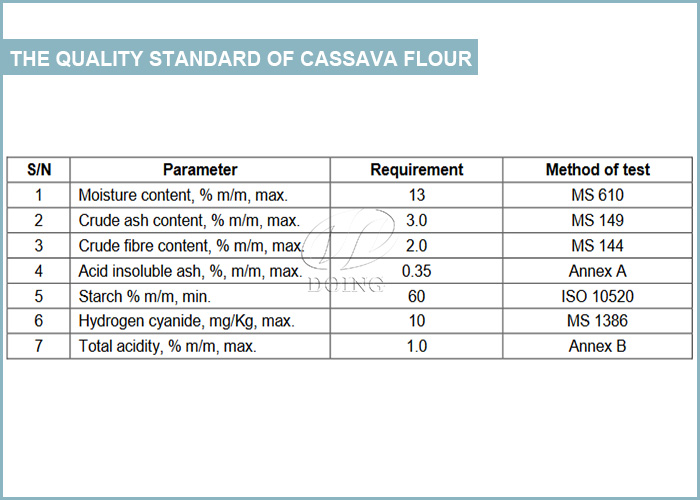

2023-10-07The quality standards of cassava flour can vary depending on the intended use and regional regulations. However, in general, there are certain parameters that are commonly considered for assessing the quality of cassava flour. Some important quality standards include:

Moisture Content: The quality standards of cassava flour have a specified maximum moisture content to ensure its stability and prevent microbial growth. The acceptable moisture content may vary but is typically below 13%.

Fiber Content: The fiber content in high-quality standard cassava flour should be within a certain range from 1%-4%. Too much fiber can affect the texture and functionality of the flour, while too little fiber may indicate excessive processing or poor quality raw materials.

Crude ash content: The quality standards of cassava flour require a low crude ash content to ensure that it meets the required purity standards. Typically, cassava flour with a crude ash content of less than 3% is considered of high quality. Excessive levels of crude ash in cassava flour can affect its functionality and shelf life. Higher levels of ash can contribute to the flour's darkening, increased bitterness, and reduced water absorption capacity, which can affect the quality of the final product.

The quality standards of cassava flour

The quality standards of cassava flour

Starch Content: High-quality cassava flour typically has a high starch content. Generally, cassava flour with a starch content above 60% is considered good. The starch content directly affects the functional properties of cassava flour. Higher starch content contributes to better binding capacity, texture development, and thickening ability. Additionally, it also affects the color and flavor of the final products.

Color: The color of standard cassava flour can vary depending on the processing methods and variety of cassava used. However, a good-quality cassava flour should have a uniform and consistent color without any discoloration or dark spots.

Taste and Odor: The quality standards of cassava flour claims the flour should have a neutral taste and odor, free from any musty or off-putting smells. Unpleasant tastes or odors may indicate improper processing, fermentation, or storage conditions.

Microbiological Standards: Cassava flour should meet specific microbiological standards to ensure safety and prevent contamination. This includes limits for bacteria, yeast, molds, and other potential harmful microorganisms.

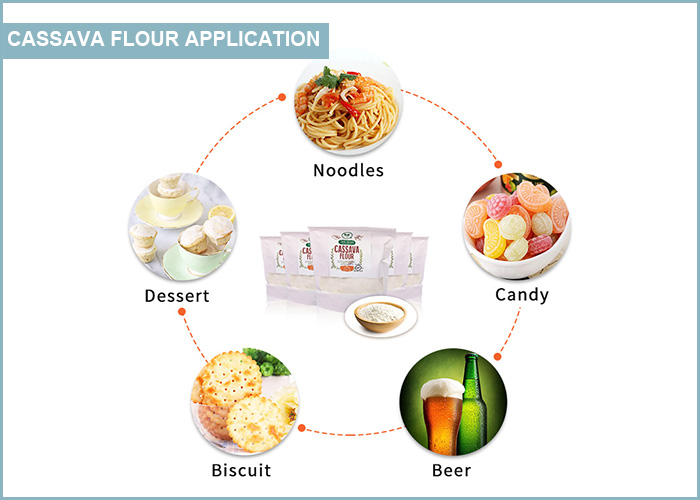

The high quality standard cassava flour produced from fresh cassava roots has a wide application, especially in the food industry, such as production of bread, biscuits, beer, beverage, etc.

The applications of cassava flour

The applications of cassava flour

The above is an introduction to the quality standard of cassava flour. Moreover, given to the good prospects of high quality standard cassava flour market, the number of investors who want to involve in cassava flour business are soaring. Then how to make high-quality standard cassava flour?

Two methods to process cassava flour

Two methods to process cassava flour

To make high-quality standard cassava flour, we, Henan Jinrui, can provide different clients with completely automatic cassava flour production line or semi-automatic cassava flour processing machines which adopt the wet processing technology to help control the moisture, fiber, starch, ash content and so on in the processing section, in order to produce high-quality cassava flour. If you want to get more details, welcome to chat with us!

Recommendation: Two Processing Methods of Cassava Flour: What are the Differences between Dry and Wet Methods?

Want to know more about our products or services? Fill out the contact form below, and we’ll to get back to you and you will get the price list. Please also feel free to contact us by email or phone.( * Denotes a required field).