Blog

2022-08-05

2022-08-05There are many types of starch, the common ones are tapioca starch, potato starch, corn starch, sweet potato starch, etc. Can the equipment for producing these starches be shared? In general, Jinrui does not recommend using one set of starch production equipment to produce starch with multiple raw materials. Because when different raw materials are used to produce starch, the processing procedures of the raw materials are different, and the equipment used is also different.

Starch equipment starch production equipment

Starch equipment starch production equipment

For example, potatoes and sweet potatoes are the raw materials of tuberous rhizomes, while cassava is a long tuber. The rotary washing machine for cleaning sweet potatoes and potatoes is not suitable for cassava, which is easy to cause equipment blockage or damage. In addition, tapioca starch particles are relatively larger than potato starch and sweet potato starch particles, if the tapioca starch milk is processed by the vacuum dehydrator in the starch equipment for sweet potatoes and potatoes, it is not only easy to cause starch loss, but also the dehydration effect does not meet the requirements.

But, potatoes and sweet potatoes' raw materials both are tuberous rhizomes. Can they share a set of the starch production equipment? Generally, it is not possible. Because the starch content, impurity content, and crushing difficulty of potatoes and sweet potatoes are very different, engineers will configure different machines for them. For example, the starch content of potato raw materials is lower than that of sweet potatoes, and it is rich in impurities. If sweet potato starch equipment is used to process potatoes, the starch centrifugal sieve in the slag removal section cannot remove the fibers in the potato pulp very well. Therefore, potato starch equipment is generally equipped with fine fiber sieve for extracting starch.

Starch extraction equipment

Starch extraction equipment

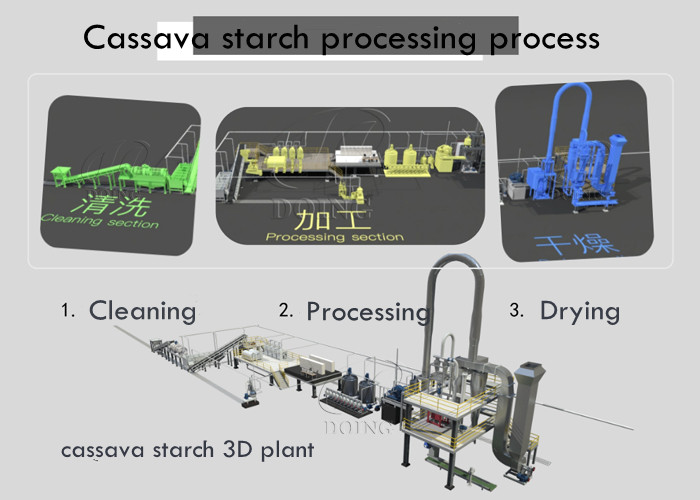

In addition, the processing technology of corn starch is very different from that of cassava starch. The corn starch process mainly includes cleaning, soaking, coarse crushing, germ separation, fine crushing, starch screening, protein separation, dehydration, and drying, while the cassava starch process mainly includes cleaning, crushing, slag removal and purification, dehydration and drying. In the two starch processes, only the starch centrifugal sieve and the airflow dryer can be shared among the starch equipment used. [Read also: The method of processing cassava into starch]

Cassava starch process

Cassava starch process

Henan Jinrui Food Engineering Technology Co., Ltd. has been engaged in the field of cassava deep processing for more than ten years and has rich experience in project cooperation. Our engineers can design a starch production line for you according to the characteristics of the raw materials processed by customers and the actual situation, so as to maximize the benefits!

Want to know more about our products or services? Fill out the contact form below, and we’ll to get back to you and you will get the price list. Please also feel free to contact us by email or phone.( * Denotes a required field).