Blog

2023-07-26

2023-07-26In recent years, with the continuous development of African industry, more and more people have crowded into the food processing industry. cassava starch, with its rising profit, has become the first choice of many customers. Here we will give you some suggestions for investing cassava starch making machinery for starch processing.

Suggestions for investing cassava starch making machinery

Suggestions for investing cassava starch making machinery

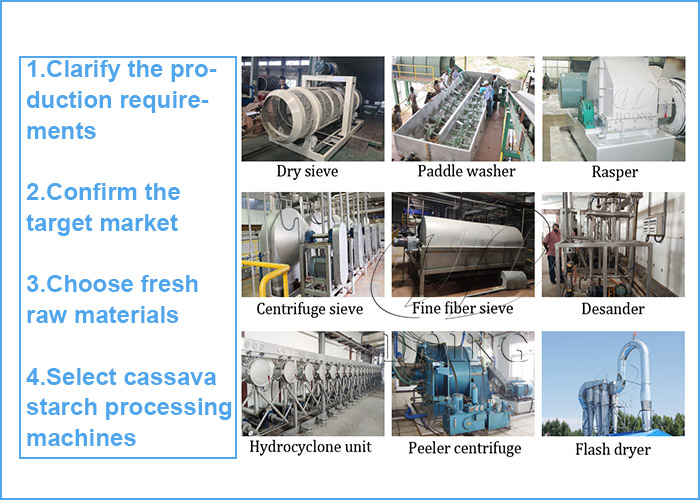

The first suggestion for investing cassava starch making machinery is that you need to clarify the production requirements. For example, how much fresh cassava are required per day, how about the the daily working hours, whether there is a support for all-day production of power supply, and how to deal with the water issues , etc. Based on these plans for the early stage, you can estimate the budget invested in the starch production and the projected profits.

The second suggestion for investing cassava starch making machinery is confirming the target market which is very critical. That means you choose to export to overseas markets or just to sell in the local market. Because of the different standards that the international market standards being relatively higher than the local market standards in Africa, the number of machines will be more, and the price will be relatively higher.

Suggestions for investing cassava starch making machinery

Suggestions for investing cassava starch making machinery

The third suggestion for investing cassava starch making machinery is the choice of raw materials. We would recommend to use fresh cassava tubers directly in the processing of cassava starch, because their starch extraction rate and starch content is higher compared with the pre-dried or dried cassava tubers. With the rising of instantaneous temperature during the crushing process, part of the starch of pre-dried or dried cassava tubers is easy to heat paste, which will affect the separation of starch and pomace in the sieving section and due to the flow of the trough separation is not easy to precipitate, the final qualified flour output rate will also be influenced. Finally, the viscosity of the finished tapioca starch processed from dried cassava will be insufficient, resulting in unusable.

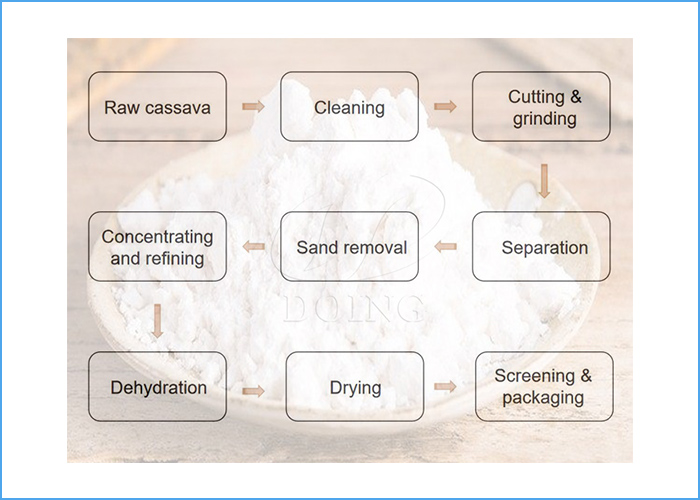

The last suggestion for investing cassava starch making machinery is the selection of cassava starch processing machines. Generally speaking, the processing flow of cassava starch is like this: cleaning-washing-cutting-crushing-separating-desanding-refining-dewatering-drying.

Processing flow of cassava starch processing

Processing flow of cassava starch processing

Fresh cassava tubers firstly will enter a dry sieve and a paddle washer for the primary cleaning, then will be conveyed to a cutting machine and rasper to be cut and crushed into cassava slurry, which later will be separated by a centrifuge sieve and a fine fiber sieve to remove the fibers. After this, the desander will remove possible fine sand and reduce ash. Next is the refining and thickening process, the hydrocyclone station will get rid of the protein and cell saps in the slurry to reach this aim. Then a peeler centrifuge will remove the exceed moisture of pure cassava slurry and a flash dryer will dry the qualified starch powder.

Machines configured in different sections are as follows:

Cleaning: dry sieve

Washing: paddle washer

Cutting: cutting machine

Crushing: cassava rasper

Separating: centrifuge sieve/ fine fiber sieve

Desanding: desander

Refining: hydrocyclone station

Dewatering: peeler centrifuge

Drying: flash dryer.

Hope all the suggestions for investing cassava starch making machinery for starch processing can give you some help. And if you want to learn more about the equipment specifications and technical parameters of cassava starch processing machines, welcome to contact us!

Want to know more about our products or services? Fill out the contact form below, and we’ll to get back to you and you will get the price list. Please also feel free to contact us by email or phone.( * Denotes a required field).