Blog

2022-03-30

2022-03-30Potato cleaning equipment displayed as following is commonly and suitably used in wet method potato starch production line.

Dry sieve

Dry sieve

Dry Sieve:

Dry sieve is the first cleaning equipment used in potato starch production. It is mainly used to remove dirt, sand, small stones, weeds and other impurities on the surface of potato. Fresh potato harvested from wet field will be transported into this dry sieve through feeding hopper and belt conveyor. After this dry sieve, a certain kind of impurities will be removed. However, there are still some sands attached on those fresh potato because fresh potatoes is still not fully washed by water. Therefore, fresh potato have to secondly clean in the next machine.

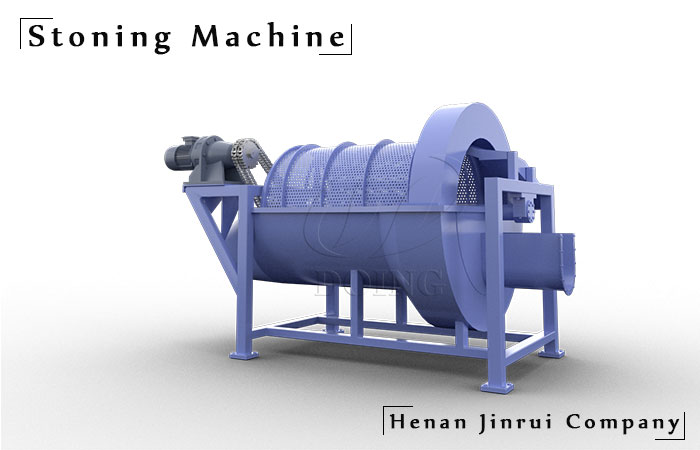

Stoning machine

Stoning machine

Stoning Machine:

Stoning machine is used to remove sands on the surface of potatoes. With special design, sands on the surface of fresh potatoes can be fully removed. This machine is indispensable in the potato starch production as it affects the purity of potato starch. As we all know, potato starch could not allow sands contained in it. In other words, you should match this machine into your potato starch production plant if you plan to start this profitable business.

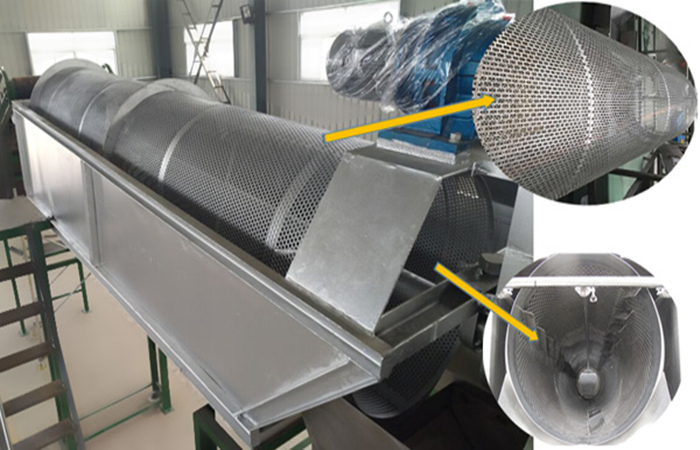

Rotary drum machine

Rotary drum machine

Rotary drum sieve:

Rotary drum sieve is also called rotary washing machine in the potato starch production plant. As I said above, fresh potatoes is still not fully cleaned and washed by water. So, the third and the final equipment rotary drum sieve will fully wash the fresh potatoes with clean water. The working principle of this cleaning equipment is that fresh potatoes flow in the opposite direction against water in the cleaning tank, which makes washing completely with good efficiency. Such washing principle is also called countercurrent washing.

Though these three cleaning equipment in potato starch production plant, fresh potatoes will be completely cleaned. This also said that these fresh cleaned potatoes can be processing into potato starch in the next two part, including processing part and drying part. These two crucial parts in potato starch production will adopt other potato starch processing machines.

Henan Jinrui Companydevelops and commercialized the equipment for the starch processing industry worldwide. Our products portfolio include a range of different technologies to provide our end customer with technology for producing high-quality potato starch as purely and efficiently as possible.

Except for potato cleaning equipment in potato starch production, we can also provide the entire starch production equipment involving cassava, sweet potato starch production equipment. We are adamant about creating productions that focus on zero-waste and full valorisation. If you need starch processing equipment, welcome to leave message to us.

Want to know more about our products or services? Fill out the contact form below, and we’ll to get back to you and you will get the price list. Please also feel free to contact us by email or phone.( * Denotes a required field).