Blog

2021-01-29

2021-01-29Sweet potato starch can be produced from fresh sweet potatoes through cleaning, washing, crushing, separation of fibers, starch refining, dewatering, drying and sieving. Machines can be used for sweet potato starch processing include dry sieve, rotary washing machine, cutting machine, rasper, centrifuge sieve, hydrocyclone station, vacuum dehydrator, flasher dryer and starch sifter. Next we will introduce these machines one by one in the different sections.

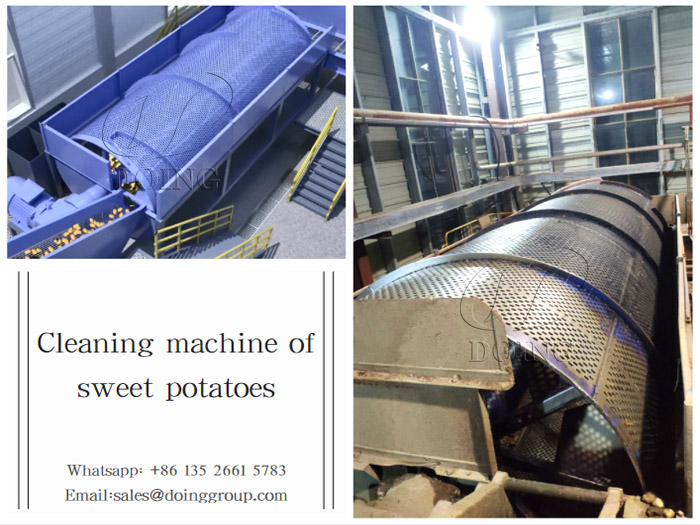

The first is cleaning section. Machines used in this section are dry sieve and rotary washing machine.

Firstly dry sieve machine can remove impurities attached on the surface of sweet potatoes, then rotary washing machine will be installed subsequently to wash sweet potatoes completely. The rotary washing machine is specially designed for round shape material like potatoes and sweet potatoes.

Cleaning section for sweet potato starch processing

Cleaning section for sweet potato starch processing

The second is processing section, sweet potato starch will be extracted and purified in this section. Machines used in this section are cutting machine, rasper, centrifuge sieve and hydrocyclone.

Firstly cleaned sweet potatoes will be cut into small pieces by the cutting machine, and then sweet potato pieces falls down to the rasper machine for complete crushing to get starch released as much as possible. Next sweet potato mash will go through centrifuge sieve group to separate fibers. Then protein and cell liquids will be removed by hydrocyclone station machine. In this process, we can get purified starch slurry as output.

Processing section for sweet potato starch making

Processing section for sweet potato starch making

The last is drying section, we can get dried sweet potato starch as final product in this section. Machines used in this section include vacuum dehydrator, flash dryer and sieving machine.

Firstly purified starch slurry will be pumped into vacuum dehydrator for dewatering process. After it, we can get wet starch with moisture content around 40%. The wet starch will be latter transported to flash dryer for last drying process with around 18% starch moisture content. To get high quality starch with uniform fineness, starch sifter is applied at last step.

The above is the brief introduction of machines can be used for sweet potato starch processing. If you are interested in setting up a factory to produce sweet potato starch, welcome to your inquiry.

Want to know more about our products or services? Fill out the contact form below, and we’ll to get back to you and you will get the price list. Please also feel free to contact us by email or phone.( * Denotes a required field).