Blog

2025-10-29

2025-10-29No matter small setups handling 3–5 tons of fresh cassava per day or fully automated fufu processing lines processing 20–80 tons daily, they cannot work all the time without proper maintenance which is crucial to ensure operational efficiency, product quality, and equipment longevity. Then what does the maintenance cost of fufu flour processing equipment include? Let's broken them down.

1. Spare Parts and Consumables

A significant portion of maintenance costs of fufu flour processing equipment comes from spare parts and consumables. During the initial purchase of equipment, it is advisable to procure commonly worn or damaged parts. These may include:

- Peeling machine blades or abrasive surfaces

- Crushing machine hammers or cutters

- Screens and filters for milling and drying systems

- Hydraulic seals and pumps for dewatering presses

- Conveyor belts and bearings

Having these parts on hand minimizes downtime when replacements are needed.

cassava peeling machine

cassava peeling machine

2. Routine Cleaning and Lubrication

Daily and weekly maintenance tasks are essential to prevent premature wear and failure. This includes:

- Cleaning: Residual cassava paste and flour can harden and clog machines. Regular cleaning of equipment such as paddle washers, crushers, and sifters is necessary.

- Lubrication: Moving parts in machines like desanders, peelers, and hydraulic presses require periodic lubrication to reduce friction and prevent overheating.

While these tasks may not always involve direct monetary costs, they require labor and time, which contribute to operational expenses.

cassava cleaning machines

cassava cleaning machines

3. Scheduled Servicing and Inspections

For medium and large-scale plants with automated fufu flour processing lines such as flash dryers and packaging machines, scheduled servicing is critical. This may involve:

- Electrical system checks

- Calibration of sensors and automated controls

-Inspection of heating elements in drying systems

- Testing of hydraulic components

Such inspections often require specialized technicians, especially for advanced automated fufu processing lines, adding to maintenance costs.

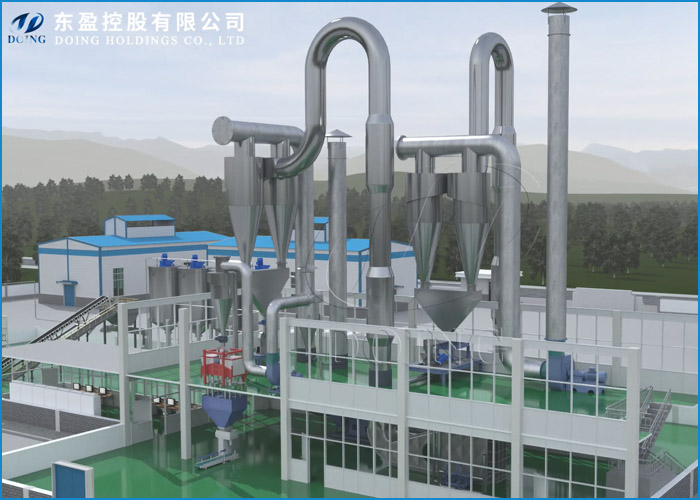

fufu flour flash dryer

fufu flour flash dryer

4. Unexpected Repairs and Downtime

Even with proper care, unexpected breakdowns can occur—especially if fufu flour processing equipment is overused. For instance, operating machines continuously for 12 hours or more can lead to motor burnout or mechanical failure. Costs in this category include:

- Emergency replacement parts

- Labor for urgent repairs

- Loss of production during downtime

To minimize such costs, it is important to adhere to recommended operating hours and avoid overloading fufu equipment.

Whether you run a small, medium, or large-scale fufu flour processing plant, a proactive maintenance approach will save time and money in the long run—and ensure the consistent production of high-quality fufu flour. Focus Henan Jinrui! We will timely offer information related to cassava and cassava processing!

Want to know more about our products or services? Fill out the contact form below, and we’ll to get back to you and you will get the price list. Please also feel free to contact us by email or phone.( * Denotes a required field).