Blog

2020-08-21

2020-08-21In the potato starch production and processing industry, the better the quality of the final potato starch, the higher the income. Therefore, potato starch manufacturers constantly pursue high-quality starch to bring higher benefits to themselves. What is the reason for the excessive impurities in the finished potato starch? Only understand the reasons first, we can do the right thing to promote our business.

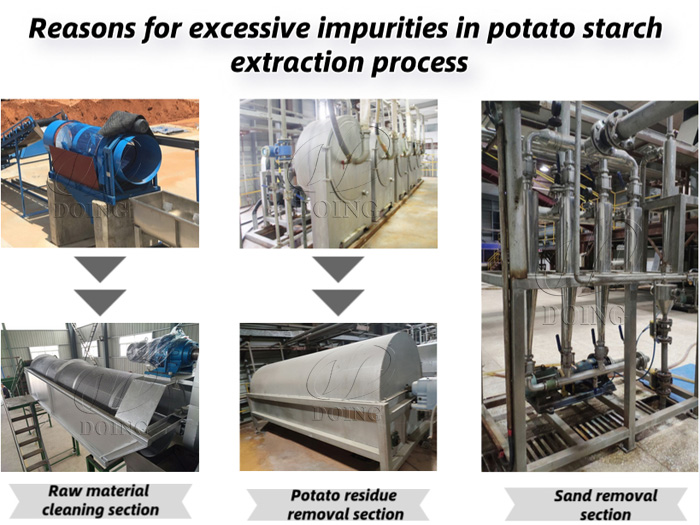

The reasons for excessive impurities in potato starch extraction process can be analyzed from 3 sections. They are raw material cleaning section, potato residue removal section and sand removal section.

Reasons for excessive impurities in potato starch extraction process

Reasons for excessive impurities in potato starch extraction process

Raw material cleaning section: Potato raw material cleaning is one of the important sections that affect the quality of final potato starch. The reasons for excessive impurities in potato starch extraction process is that the cleaning process is not strictly controlled and the cleaning strength is not enough, which increases the amount of sediment into the starch. Doing Holdings - Henan Jinrui uses 2 potato starch production equipment in cleaning section, dry sieve and rotary washing machine. The effect of removing impurities in potato starch extraction process is obvious and it also has the function of peeling.

Potato residue removal section: The fiber component in the potato raw material slurry will cause the finial potato starch to taste poor. So it is important to remove the fiber in the potato raw material slurry. When sieving out potato residues, some manufacturers use a low mesh size, which causes a lot of fine residues (crude fibers) to leak into the sieve together with starch milk, and use the same coarse sieve to filter the second precipitation, or simply without secondary filtration, the fine residue is easily mixed with the small granular starch, resulting in an increase in the amount of impurities such as crude fiber in the starch. At present, the potato starch processing machine designed by Doing Holdings - Henan Jinrui adopts two types of potato starch production and processing equipment, a centrifugal screen with a high mesh screen and a fine fiber sieve machine, to remove potato dregs, and the slag removal effect is very good.

Sand removal section: In addition to the raw material cleaning section of the finished potato starch, the sand removal section may also cause excessive impurities in potato starch extraction process. Therefore, in order to improve the quality of the finished potato starch and remove the silt in the potato starch, a desander should be equipped in potato starch extraction process and coordinate with other potato starch making machine to remove impurities.

Desander in potato starch extraction process

Desander in potato starch extraction process

In addition to the above 3 reasons, the reasons for excessive impurities in potato starch extraction process may be the processing technology. In the process of producing potato starch using non-sealed processing technology, it is easy to be affected by environmental factors, causing potato starch to brown or adulterate dust. Therefore, it is necessary to choose potato starch production and processing equipment with sealed processing technology.

High-quality potato starch is the first choice of customers. Analyzing the reasons for excessive impurities in potato starch extraction process and then solving the problems can greatly increase economic benefits. If you have any questions, you can send it to us, and we will give you a detailed answer as soon as possible.

Want to know more about our products or services? Fill out the contact form below, and we’ll to get back to you and you will get the price list. Please also feel free to contact us by email or phone.( * Denotes a required field).