Blog

2021-01-07

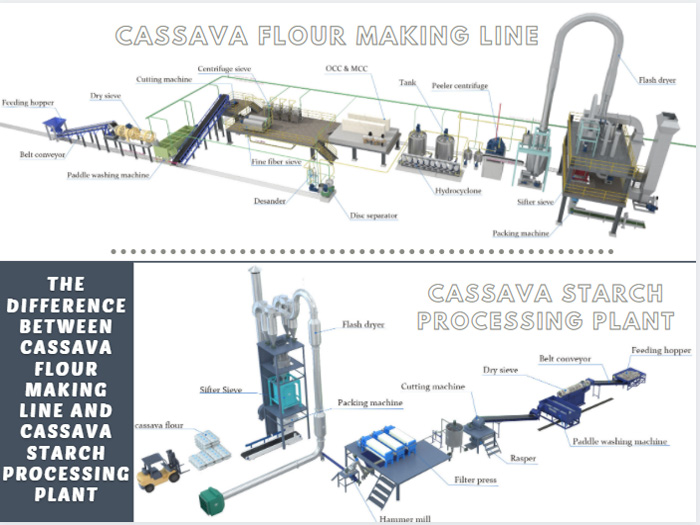

2021-01-07Cassava flour and cassava starch are 2 different products that are produced from cassava tubers. Also required machines are different. This article will briefly introduce the difference between cassava flour making line and starch processing plant.

Cassava flour making line and cassava starch processing plant

Cassava flour making line and cassava starch processing plant

The first is cleaning section.

Both of cassava flour making line and cassava starch processing plant have cleaning section which include dry sieve and paddle washing machine. The difference lies in the design of paddle washing machine.

Because cassava flour making line has a high requirement for cassava peeling, paddle washing machine is specially designed. It has 2 functions of peeling and washing. Besides, there are 3 slots in paddle washing machine. Dry grinding and wet washing are carried out simultaneously. In contrast, the function of paddle washing machine in cassava starch processing plant is relatively simple which only can wash cassava tubers. Because the function of peeling is scattered to the later processing section.

Then it’s processing section.

In cassava flour making line, cassava is directly dehydrated and dried after crushing process. And then we can get cassava flour as finished product. While in cassava starch processing plant, before dehydration and drying, some other contents like fibers, protein, cell liquids etc, should be separated firstly. The process is relatively fine and complex. There are some machines are specially used in starch production line: centrifuge sieve machine is to separate fibers, hydro-cyclone is to separate protein and cell liquids and concentrate starch milk.

The last step is dewatering and drying.

Because cassava flour and cassava starch have different characteristics, different dehydrator machines are applied. In cassava flour making line, plate and frame filter press machines is used for dehydration. While in cassava starch plant, vacuum dehydrator or peeler centrifuge is used for dewatering process.

Although there are several differences for cassava flour making line and cassava starch processing plant, they all use fresh cassava tubers as raw materials and have almost the same machines for cleaning process. Therefore, some machines can be shared for cassava flour making line and cassava starch processing plant. And one combined line process 2 products is also workable. For detailed solution, please contact us: Whatsapp: +86 135 2661 5783.

Want to know more about our products or services? Fill out the contact form below, and we’ll to get back to you and you will get the price list. Please also feel free to contact us by email or phone.( * Denotes a required field).