Blog

2023-12-01

2023-12-01Henan Jinrui Company often receives inquiries from Kenyan customers about cassava flour production lines. For small investors, machines with smaller investment capabilities are more suitable for them.

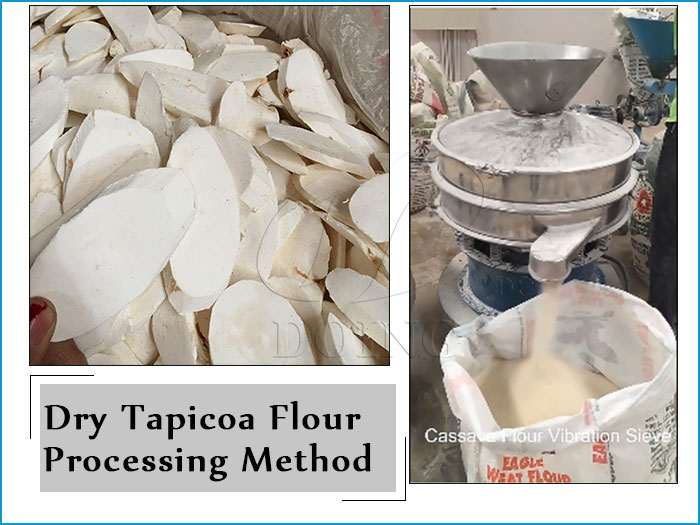

There are two methods of processing cassava flour on the market. One is to grind cassava chips into powder, which we call the dry method. The other is the wet method, in which fresh cassava tubers are washed, peeled, graded, moisture removed, dried, sieved, and processed into flour. Both of these cassava flour production lines can be provided by Henan Jinrui Company. Today I will introduce these two small input cassava flour production lines.

Dry method cassava flour production machine

Dry method cassava flour production machine

The dry method is to cut fresh cassava tubers into slices, dry them in a dryer or in the sun, and then grind the cassava slices into powder. Cassava inputs range from 1 ton/hour to 20 tons/hour. The machines include feeding hopper, quantitative auger, magnetic separator, hammer crusher, fine mill machine, high-pressure pulse dust collector, and packaging machine.

Fresh cassava tubers are processed into flour using the wet method. Fresh cassava tubers need to be washed, peeled, graded, moisture removed, dried and sieved. The production capacity can range from 1 ton/hour of cassava input to 40 tons/hour of input. Small cassava flour production lines can be designed as semi-automatic and fully automatic, and customers can choose according to the machine's budget.

Fully automatic cassava flour production line

Fully automatic cassava flour production line

The semi-automatic cassava flour production line includes peeling machine, grater, hydraulic press, flash dryer, fine mill machine, and vibration sieve.

Fully automatic cassava flour production line includes dry sieve, paddle washer, peeling machine, cutting machine, rasper, de-sander, filter press, flash dryer, vibration sieve, and automatic packaging machine.

Henan Jinrui Food Company has been engaged in cassava machinery manufacturing for more than 12 years, including cassava machinery, potato starch machinery, and sweet potato starch machinery. If customers are interested in investing in cassava flour production line projects in Kenya or other countries, please feel free to inquire.

Want to know more about our products or services? Fill out the contact form below, and we’ll to get back to you and you will get the price list. Please also feel free to contact us by email or phone.( * Denotes a required field).