Blog

2025-10-31

2025-10-31For investors seeking lucrative opportunities, the cassava flour processing industry offers a golden gateway to tap into the booming demand for gluten-free, affordable, and nutritious alternatives to traditional wheat flour. This article explores why cassava flour is the future of bread production and how investing in modern processing machinery can transform this humble tuber into a sustainable revenue stream.

The Rising Demand for Cassava Flour in Bread Making

The global shift toward gluten-free diets, driven by health consciousness and dietary restrictions, has boosted the demand for cassava flour in bread making. Unlike wheat flour, cassava flour is naturally gluten-free, making it ideal for producing bread, cakes, and pastries for consumers with celiac disease or gluten intolerance. Here’s why cassava flour is gaining traction:

cassava flour vs wheat flour

cassava flour vs wheat flour

Nutritional Benefits: Cassava flour is rich in carbohydrates, dietary fiber, and essential minerals like calcium and potassium. Its neutral flavor allows it to blend seamlessly with other ingredients, ensuring delicious outcomes.

Cost-Effectiveness: With wheat prices fluctuating due to climate change and supply chain disruptions, cassava flour offers a low-cost, locally sourced alternative that reduces dependency on imports.

Market Growth: The gluten-free product market is projected to exceed $8.3 billion by 2025, with cassava-based products leading the charge in regions like Africa, Asia, and Latin America.

For bakers and food manufacturers, incorporating cassava flour into bread recipes not only caters to health trends but also lowers production costs while maintaining quality. However, the key to success lies in producing high-quality manioc flour that meets industry standards—a goal achievable only with advanced cassava flour processing machinery.

Transforming Cassava Into Premium Flour: Advantages of Cassava Flour Processing Machinery

Producing cassava flour for bread requires precision and consistency. Traditional methods often result in uneven texture, impurities, or microbial contamination, rendering the cassava flour unsuitable for commercial baking. Here’s how investing in a semi- or fully automated cassava flour processing line can ensure superior quality and profitability:

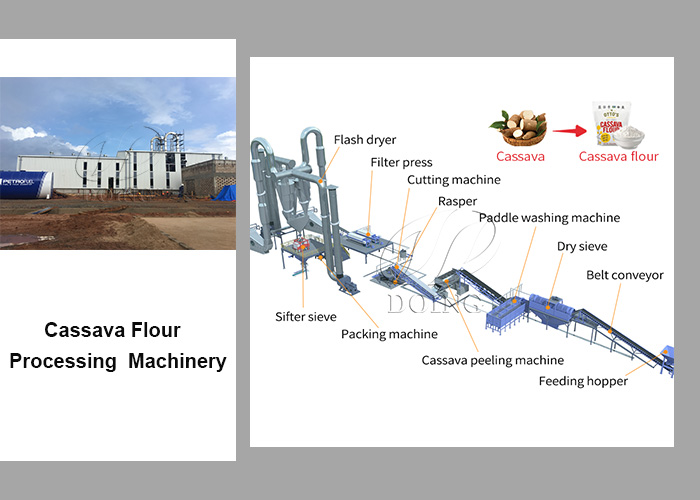

cassava flour processing machinery

cassava flour processing machinery

1. Cassava Cleaning and Peeling Unit

Function: Removes dirt, stones, and sand from raw cassava tubers while efficiently peeling the skin.

Machinery Features:

Dry Sieve: Rotatos quickly to get rid of the stones and sand on raw cassava tubers.

Paddle Washer: Uses counter-current water flow to achieve a 95% cleaning rate, eliminating contaminants that affect flour safety.

Abrasive Cassava Peeler: Adjustable rollers adapt to tuber sizes, ensuring minimal flesh loss and maximizing yield.

Impact: Clean, peeled cassava forms the foundation for impurity-free flour, critical for bread texture and taste.

cassava peeler

cassava peeler

2. Cassava Grating and Dewatering System

Function: Breaks down cassava into fine pulp and removes excess moisture to extend shelf life.

Machinery Features:

High-Speed Rasper: Equipped with stainless steel saw blades to create ultra-fine mash within minutes. This step determines the flour’s smoothness.

Plate-Frame Filter Press: Reduces moisture content from 60% to 40% in under 30 minutes, preventing mold growth and facilitating drying.

Impact: Fine, dewatered pulp ensures the cassava flour’s light texture, which is vital for soft, fluffy bread.

cassava grater

cassava grater

3. Cassava Flour Drying and Milling Unit

Function: Dries the cassava mash into brittle granules and mills them into uniform flour.

Machinery Features:

Flash Dryer: Uses controlled temperatures to dry wet cassava cakes without degrading nutrients, preserving the flour’s natural color and flavor. The final moisture is about 12-14%, meeting the production standard of high quality cassava flour.

Fine Mill: Grinds dried cassava flour into 80–100 mesh flour, matching the fineness of premium wheat flour.

Impact: Consistent particle size allows for better dough elasticity and rising, ensuring bakery-grade results.

flash dryer

flash dryer

4. Cassava Flour Sieving and Packaging Station

Function: Removes lumps and impurities before packaging the cassava flour for market.

Machinery Features:

Sifter Sieve: Multi-layer sifting technology delivers smooth, lump-free cassava flour.

Auto-Packaging Machine: Weights and seals flour in airtight bags, maintaining freshness and compliance with food safety standards.

Impact: Professional packaging enhances shelf appeal and builds trust with buyers.

Why Invest in Cassava Flour Processing Now?

Profit Margins: With a 30–40% return on investment, cassava flour production outperforms many agribusiness ventures. A ton of raw cassava (costing $100–$150) can yield flour worth $500–$700 in retail markets.

Government Support: In countries like Nigeria, Ghana, and Kenya, subsidies and grants are available for agro-processing initiatives, reducing initial capital outlay.

Export Potential: Europe and North America are increasingly importing gluten-free flours from Africa, creating opportunities for international trade.

Whether you’re a farmer, baker, or investor, integrating modern cassava flour processing machinery into your operations can unlock unprecedented growth. At Henan Jinrui, we provide end-to-end solutions—from machinery supply to operational training—to help you dominate the cassava flour market.

Want to know more about our products or services? Fill out the contact form below, and we’ll to get back to you and you will get the price list. Please also feel free to contact us by email or phone.( * Denotes a required field).