Blog

2025-06-27

2025-06-27Garri processing technology and making equipment configuration directly affect product quality and production efficiency. As a professional cassava processing equipment manufacturer, Henan Jinrui Food's Garri production line configuration plan has attracted much attention. This article will analyze in detail the two main configuration methods of Henan Jinrui Food Garri processing equipment: integrated connection equipment (attached together) and decentralized separate equipment, providing comprehensive technical references for potential customers.

Small capacity garri processing equipment

Small capacity garri processing equipment

Garri Making Separate Machines Configuration Introduction

Henan Jinrui's garri making separate machines adopt modular design, and each processing equipment operates separately. It is usually suitable for small-scale garri processing projects of 1-4TPD. The garri single equipment configuration usually includes peeling machine, grinder, hydraulic press, garri frying machine, and vibration sieve:

Cassava Peeling Machine: Used for cassava peeling, remove the cassava peels for garri making.

Cassava Grinding Machine: Crushing the fresh cassava into cassava mush.

Hydraulic Press: Removing moisture from cassava mush.

Garri Frying Machine: Frying the cassava cake into high quality garri.

Vibration Sieve: Ensuring the garri particle uniform.

Advantages:

- Low investment cost

- High flexibility (can be procured in stages)

- Suitable for small-scale garri production

- Easy to maintain

Complete garri production line

Complete garri production line

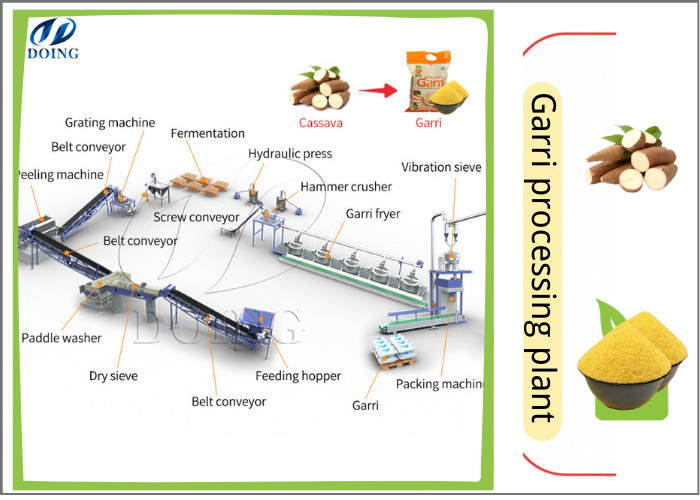

Configuration of Garri Making Equipment Attached Together (Integrated Connection)

When the daily feeding reaches 5 tons or more, an integrated garri equipment configuration (garri production line) is often selected. The garri processing equipment of each process is directly attached together through a belt conveyor to reduce manual intervention. Compared with the garri making separate machine, Henan Jinrui's garri production line configuration has added a feeding hopper, dry sieve, paddle washing machine, and packaging machine to ensure the efficient and stable operation of garri production. At the same time, it also adds a belt conveyor to attach various garri making equipment to ensure the smoothness of garri production:

Feeding Hopper: Used for the raw material transportation.

Dry Sieve: Removing the mud and weed impurities attached to the surface of cassava.

Paddle Washing Machine: Washing the cassava skins.

Packaging Machine: Packing the final product, garri for sale or storage.

Belt Conveyor: Attach the separate garri making machines.

Advantages:

- High production efficiency (continuous operation)

- High automation level, low labor cost

- Stable product quality

- Relatively small footprint

Factors affecting the garri making machines selection

Factors affecting the garri making machines selection

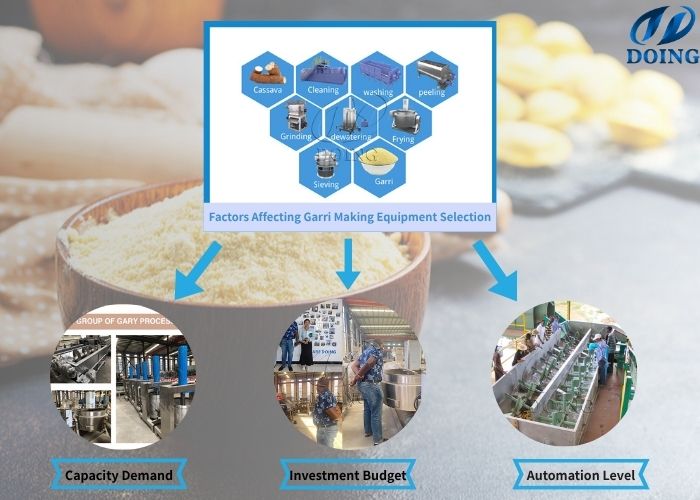

The Factors Affecting Garri Making Equipment Configuration Selection

Now that you learn about the separate equipment for garri making and complete garri production line, whether you choose Henan Jinrui's separate equipment for garri making or a complete garri production line (all garri equipment attached together), you need to consider the following factors before making a choice:

- Capacity Demand: Consider the most critical factor-capacity. Generally speaking, for a capacity of 1-4TPD, some separate equipment for garri making can be selected, but for a larger capacity, more garri processing equipment needs to be attached together to form a complete production line to improve garri production efficiency.

- Investment Budget: If you have a larger budget, you can maximize your garri processing business by purchasing a complete garri production line from Jinrui, but if you have budget limit, you can also purchase the separate equipment for garri making to improve garri production efficiency, such as cassava peeler, garri fryer etc.

- Automation Level: If you want to achieve a high level of automation, a complete garri making line is an ideal choice. The full set of garri equipment is attached together to minimize manual intervention, but if you want more labor participation in the garri making process, you can choose separate equipment for garri production.

The garri making equipment provided by Henan Jinrui includes two main configuration options: Integrated connection equipment is suitable for medium and large production enterprises, with the features of high automation, large production capacity, and good product consistency. Separate equipment configuration is more suitable for startups or small making plants, with the advantages of low investment, flexible layout, and easy gradual expansion.

Henan Jinrui can provide the professional suggestions and customized solutions to ensure the optimal equipment configuration for garri making to meet different production needs. If you need it, please feel free to contact us at any time!

Want to know more about our products or services? Fill out the contact form below, and we’ll to get back to you and you will get the price list. Please also feel free to contact us by email or phone.( * Denotes a required field).