Blog

2019-07-26

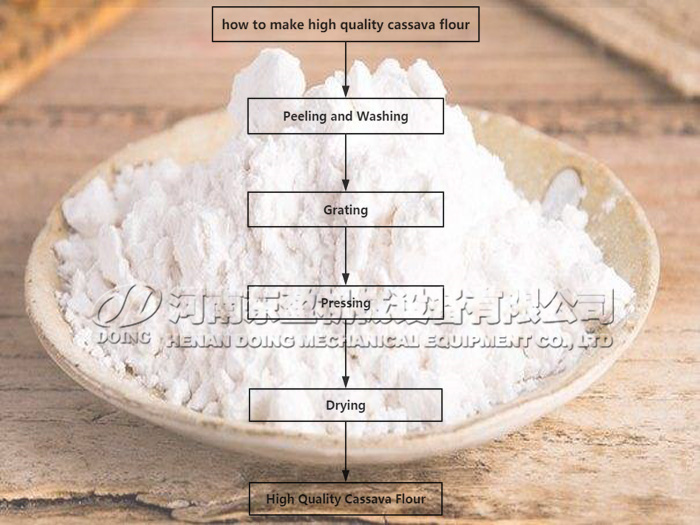

2019-07-26With the development of technology, there is a shift in the ways of processing of cassava. Modern machines can do the things that people were once forced to do by hand. At the same time, along with economic level's promotion, people also have a increasing demand for high quality cassava flour. So how to make high quality cassava flour? Generally speaking, whether manual operation or mechanized way in the cassava flour processing, they all include these steps: peeling, washing, grating, pressing and drying.

Step1: Peeling and Washing

Peeling is to separate the flesh from cassava skin and washing is to further remove dirt, sand, and incomplete removed skin are attached to the peeled root. Compared to manual operation, the machine in Doing company can peel and wash concurrently that ensures the efficiency and quality of cassava. This is the basis of high quality cassava flour with high efficiency and low consumption.

Paddle washing machine for cassava peeling and washing

Paddle washing machine for cassava peeling and washing

Step2: Grating

Before grating, the cassava had better cut into pieces so as to better grate. The washed and peeled cassava are disintegrated with addition of water into mash by rasper without lump. The smoothness of the mash determines the quality, yield and market value of the finished high quality cassava flour.

Rasper for cassava grating

Rasper for cassava grating

Step3: Pressing

The mash should be removed as much moisture as possible from an initial level to less than 30%. Pressing should be done immediately after grating to avoid fermentation after grating. Complete pressing facilitates drying in high quality cassava flour processing. Pressing also removes much of the yellow color of cassava, resulting in a more acceptable white product.

Filter press for cassava pressing.

Filter press for cassava pressing.

Step4: Drying

Drying is often at the end of the processing. In traditionally, sun-drying is applied to the drying. It is so slow and cumbersome. The more rapid the drying is, the higher the quality of final products are. The flash dryer in Doing is negative press drying to evaporate surface moisture instantaneously. It can dry cassava flour instantly in the gas flowing process by using high-speed flowing hot air to suspend wet flour in it. After it, the high quality cassava flour is achieved.

Flash dryer

Flash dryer

At the moment, I believe you can have a certain understanding of high quality cassava flour processing. Whether manual operation or mechanical way, they can produce cassava flour, but the quality of final produced cassava flour is different by different ways. If you want to product the cassava flour at a high speed and quality, you can contact us at any time.We can give you a factory price. A high quality cassava flour can bring a more high market value for you.

Want to know more about our products or services? Fill out the contact form below, and we’ll to get back to you and you will get the price list. Please also feel free to contact us by email or phone.( * Denotes a required field).