Blog

2019-09-06

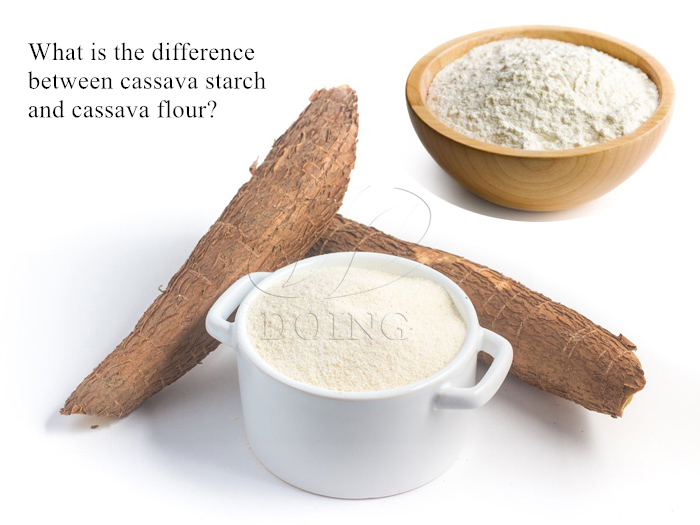

2019-09-06Cassava starch and cassava flour are both dry powers produced from cassava, but do you know their difference? Do you know why cassava starch can be widely used as a raw material for various industries while cassava flour can not? Why can cassava flour be used instead of wheat flour to make bread but cassava starch can not? If you are curious bout these issues, please read on.

What is the difference between cassava starch and cassava flour?

What is the difference between cassava starch and cassava flour?

1. First, the processing methods of cassava starch and cassava flour are different.

The processing of cassava starch is to clean the cassava first, and then to grind the cassava cells to release the starch granules in the cassava cells, but the other substances in the cassava cells, such as fiber, protein, cell liquid, etc. are also released during the grinding process. Therefore, in order to produce pure cassava starch, a series of separation steps are required. In order to ensure the quality of cassava starch, the cassava starch factory generally uses a centrifugal sieve and fine fiber sieve to separate fiber impurities, adopts desander cyclone to remove the sand in the starch and then uses a hydrocyclone system to separate other insoluble and insoluble impurities such as proteins, fats, etc. After these stages of separation and purification, the obtained pure starch slurry is dehydrated and dried into a starch powder.

Cassava starch processing technology

Cassava starch processing technology

The method of making cassava flour is relatively simple. The cassava is first cleaned and peeled, and then ground. Then we just need to remove the sand impurities which may influence the quality of cassava flour, and finally dehydrate and dry to obtain cassava flour.

Due to the different processing techniques, the cassava starch processing machine adopted is different from the cassava flour processing machine. Considering the complexity of cassava starch production, modern cassava starch processing lines are generally used to produce cassava starch. While cassava flour can be produced mechanized or semi-automatically and semi-manually.

Cassava flour processing technology

Cassava flour processing technology

2. Different processing methods lead to different properties of cassava starch and cassava flour

Because the cassava starch removes impurities other than starch, therefore it's pure white in color and has no taste. As an important member of starch, cassava starch has many starch properties. For example, cassava starch is hygroscopic and can be gelatinized and hydrolyzable. In addition, due to the complicated processing process of cassava starch, the toxicity of cassava is removed during processing, so cassava starch is non-toxic.

Different from cassava starch, cassava flour also contains fiber and other substances, so the color of cassava flour is not as white as starch. In addition, cassava flour still contains a little toxicity, especially the cassava flour produced by semi-automated processing. Therefore, cassava flour can not be eaten raw, but the toxicity of cassava flour can be removed by cooking.

Cassava starch & cassava flour

Cassava starch & cassava flour

3. Different properties determine the different usages of cassava starch and cassava flour

Cassava starch is a good industrial raw material because of its low non-starch impurity content, high viscosity, low gelatinization temperature, transparent and stable paste liquid, good film formation and strong permeability. It is widely used in food, beverage, candy, pharmaceutical, textile, paper and other industries.

Due to cassava starch has high viscosity, it can be used as an adhesive. Its paste is clear, which is suitable for coloring with pigments, and cassava starch can also be used as a thickener, puffing machine, binder and stabilizer.

As for cassava flour, it mainly used in food industry. And in Africa countries, cassava flour can be used as substitute for wheat flour for making baked goods. That is because cassava flour contains fibers, and fibers can be used as a substitute for gluten to improve the texture of some baked goods. Meanwhile, cassava flour is increasingly used in a variety of foods such as bread, noodles, and pancakes.

Though cassava starch and cassava flour are different in processing technology property and usage. But they both have great demand in Africa and the international market, especially Africa as the largest producer of cassava, still need to import cassava starch and cassava flour. Therefore starting cassava starch or flour processing business in Africa is promising. If you want to start a cassava processing business, DOING project manager can help you.

Want to know more about our products or services? Fill out the contact form below, and we’ll to get back to you and you will get the price list. Please also feel free to contact us by email or phone.( * Denotes a required field).