Blog

2020-08-26

2020-08-26Potato starch is starch extracted from potatoes which is a very refined starch, containing minimal protein or fat. Which is also very expensive compared with cassava starch, corn starch and wheat starch. Now more starch plant choose to potato starch manufacturing equipment with automatic potato starch production process to make potato starch. Next we will mainly introduce the automatic potato starch production process and potato starch manufacturing equipment.

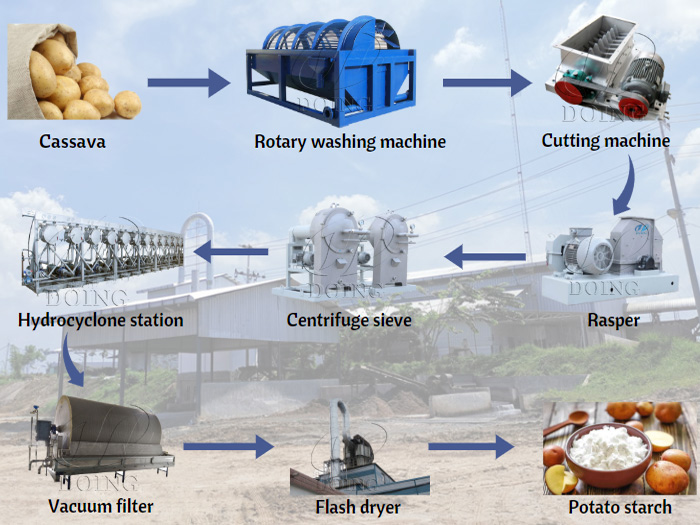

Automatic potato starch production process:

Fresh potato cleaning section - potato starch processing section - final potato starch drying and packaging section.

Potato starch manufacturing equipment:

Dry sieve - Rotary washer - Rasper - Centrifuge sieve - Fine sieve - Hydrocyclone station - Vacuum filter - Flash dryer - Starch sieving machine - Automatic packing machine - Centralized control system.

Potato starch manufacturing equipment

Potato starch manufacturing equipment

The quality index of automatic potato starch production process:

Physic - chemical index: The moisture content of final potato starch is less than 18%. Of course, if customers has a higher requirement, Doing Holdings - Henan Jinrui can customize appropriate automatic potato starch manufacturing equipment for you.

Starch quality index: pure and white color, no lumpy starch, fine, no peculiar smell, no sand and no other impurities. The whiteness of starch produced by Doing Holdings - Henan Jinrui's automatic potato starch production process can reach more than 92% which is good for sales and high economic benefit.

Safety quality index: automatic potato starch production process is standardized, bacteria and coliforms and other indexes meet national food standards. The pathogenic bacteria can not be detected, and food packaging (or vacuum packaging) do not have air leakage or damage.

Potato starch

Potato starch

Compared to manual operation, the automatic potato starch production process has many advantages:

Using automatic potato starch production process to produce potato starch will get twice the result with half the effort. Doing Holdings - Henan Jinrui’s potato starch manufacturing equipment adopts multi-level cleaning, crushing, slag removal and purification, impurity removal and other automatic potato starch production process, which are conducive to improving the whiteness, purity and fineness of the finished potato starch. Doing Holdings - Henan Jinrui uses a sealed type processing technology, the whiteness of finished potato starch can reach more than 92%. Jinrui's automatic potato starch production process uses a flash dryer in the process of wet potato starch drying. The flash dryer uses the instantaneous drying principle and a negative pressure drying system, which can not only complete the drying within 1-2 seconds, but also has a high heat exchange rate. The moisture content of the finished potato starch is less than 18%, and the negative pressure system can control the loss of raw materials, thereby increasing the starch output.

Potato starch drying machine

Potato starch drying machine

However, when using traditional manual operation to produce potato starch, if the quality of the finished potato starch has a high requirement, it will take a lot of manpower, material resources and time. When the two steps of extraction and drying are carried out, they are easily affected by other factors. During the extraction process, it is not sealed processing, and browning reaction is prone to occur, resulting in poor quality of the finished potato starch. Also during the drying process, it is easy to be affected by weather and other factors.

The potato starch manufacturing equipment manufactured by Doing Holdings - Henan Jinrui’s is made of stainless steel in contact with potato raw materials, starch milk, and wet starch. At the same time, the processing of potato starch is very fast, and the processing is completed before it can react with air which can guarantee the quality of the final potato starch. Automatic potato starch production process is a suitable choice for large-scale potato starch production. If you want to start potato starch processing business, welcome to contact us to get more information about the machine.

Want to know more about our products or services? Fill out the contact form below, and we’ll to get back to you and you will get the price list. Please also feel free to contact us by email or phone.( * Denotes a required field).