Blog

2021-11-08

2021-11-08Whiteness, purity and fineness are the three major standards for testing the quality of cassava starch in the cassava starch market. If you want to improve the quality and enhance the market competitiveness of produced cassava starch, you might as well start from these three aspects: clean cassava raw material completely, sieve the cassava starch slurry thoroughly, dehydrate cassava starch scientifically.

1.Clean cassava raw material completely

The impurities attached to cassava raw material will have a bad effect on the whiteness and purity of finished cassava starch. If the impurities are not effectively removed, it is easy to leave an intuitive impression of poor quality on cassava starch consumer groups at a glance. So we need to adopt dry sieve and paddle washing machine to cleaning cassava raw material completely and remove the impurities like weeds, little stones,dirt, mud, etc.

Dry sieve and paddle washing machine of cassava starch production line

Dry sieve and paddle washing machine of cassava starch production line

2.Sieve the cassava starch slurry thoroughly

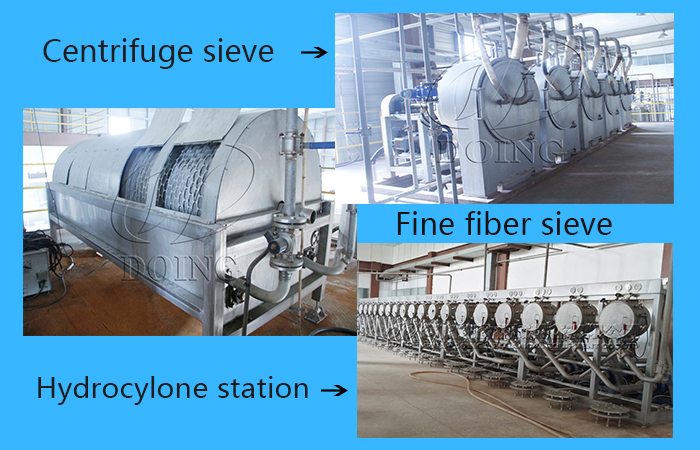

There are fiber, protein and cell in crushed cassava slurry. In order to get cassava starch with high purity and fineness, it’s necessary to take some measures to remove them off. We may adopt centrifuge, fine fiber sieve and hydrocyclone station to sieve cassava starch thoroughly, then further achieve the purpose of concentrating and dedicating cassava starch milk.

The important part to make cassava starch into puity flour

The important part to make cassava starch into puity flour

3.Dehydrate cassava starch scientifically

If the cassava starch is not dehydrated in a scientific way, the finished cassava starch is prone to agglomeration, yellowing, and even mildew. It’s recommended to adopt peeler centrifuge to decrease wet starch moisture content to 36.5% and then adopt flash dryer to dry cassava starch instantly. This dehydration way can not only help to obtain high-quality finished cassava starch with uniform moisture, high fineness an, but also improves the cassava starch processing efficiency.

Peeler centrifuge and flash dryer of cassava starch production line

Peeler centrifuge and flash dryer of cassava starch production line

If you have interests in these machines mentioned above, welcome to contact Henan Jinrui Company, a professional and leading manufacturer of cassava starch processing machine. Our cassava starch processing machine can not only guarantee the high quality of cassava starch, but also help improve the cassava starch extraction rate to maximize the processing benefits!

Want to know more about our products or services? Fill out the contact form below, and we’ll to get back to you and you will get the price list. Please also feel free to contact us by email or phone.( * Denotes a required field).