Blog

2021-12-02

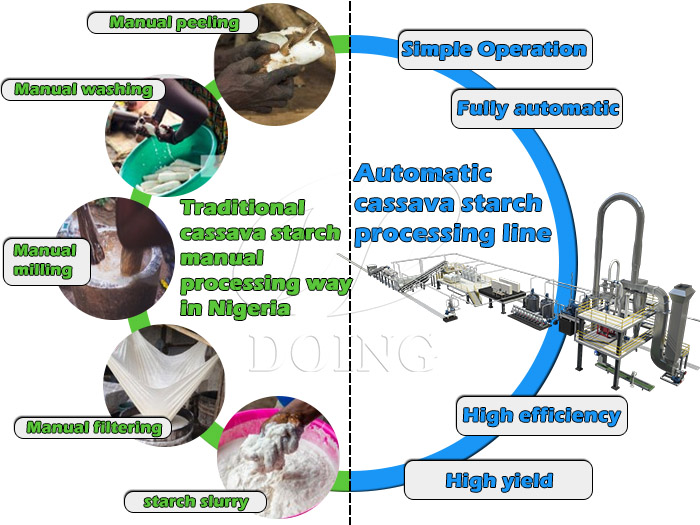

2021-12-02There are mainly two ways to process cassava into cassava starch in Nigeria. One is cassava starch manual processing way, and the other is cassava starch mechanical processing way. These two ways has their own features and application scopes.

1.Traditional cassava starch manual processing way

Cassava starch manual processing way in Nigeria is very traditional and is normally at small scale. And they usually adopt the following steps to process cassava into starch.

Traditional cassava starch manual processing way

Traditional cassava starch manual processing way

Firstly cassava is cleaned and peeled, and then cleaned cassava is crushed into pulp by simple grating machine. Then cloth is used to sieve fibers from cassava pulp. After that, cassava slurry that goes through the cloth sieve will be put into a barrel, tank or constructed pool. After several hours sedimentation, starch precipitates to the bottom of container. Next, pour out or pump the upper clean water, people can get wet cassava starch cakes. Finally, people will place wet starch cakes under sunlight to complete the drying process.

Cassava starch manual processing way cannot achieve continuous and large scale production, and the finished starch is of low quality.

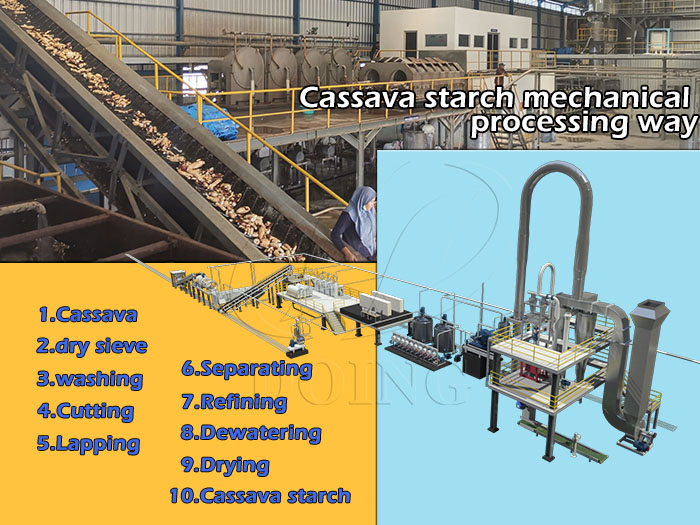

2.Cassava starch mechanical processing way

Different from manual processing way, cassava starch mechanical processing way can achieve continuous and large scale production and the finished cassava starch is of high quality.

Cassava starch machanical processing way

Cassava starch machanical processing way

The modern mechanical cassava starch processing line consists of machines for cleaning, processing and drying. In cleaning section, dry sieve is used to do preliminary cleaning of cassava raw materials and paddle washing machine is used to do thorough washing. In processing section, cassava crushing is completed by cutting machine and rasper to improve the cassava, then fiber is separated by centrifuge sieve machine, protein and cell liquids are removed by hydrocyclone station. After pure starch milk is produced, peeler centrifuge will be applied for dehydration. Finally flash dryer can achieve fast drying of starch in drying section. To keep uniform fineness of final starch, sieving machine will be installed after the dryer. All machines can be connected by conveyors, making the whole cassava starch production process completed automatically.

By comparison, the mechanical processing way is more suitable for modern cassava starch processing line. But there is no professional manufacturer of cassava starch processing machine in Nigeria, and most cassava starch processing plants import equipment from China. Henan Jinrui has helped many customers in Nigeria install the cassava starch processing machine for 10+ years. And we even have oversea warehouse in Nigeria. We can customize complete cassava starch processing line from raw cassava input to final starch output for you.

If you have plans to set up a cassava starch processing plant and want to achieve large capacity production and high quality of final starch, feel free to contact Henan Jinrui to get more details. Our project manager can give you professional advice based on your plan.

Want to know more about our products or services? Fill out the contact form below, and we’ll to get back to you and you will get the price list. Please also feel free to contact us by email or phone.( * Denotes a required field).